Mounting MSR1 to the CMM

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 88 KB | Rozměry: 760 x 593 px

Výrobní řady: CMM probes, software and retrofits

retrofit CMM cables EUD2018-046

Typ obsahu: Stažení | Jazyk: English | Přípona souboru: pdf | Velikost souboru: 2 MB

Výrobní řady: CMM probes, software and retrofits

ACR1 autochange rack on CMM

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 11 KB | Rozměry: 180 x 234 px

Výrobní řady: CMM probes, software and retrofits

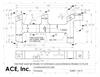

Individual component diagram, ACE CMM.

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 21 KB | Rozměry: 390 x 300 px

Výrobní řady: CMM probes, software and retrofits

M6 CMM clamping kit B

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 1 MB | Rozměry: 5117 x 3018 px

Výrobní řady: Fixtures

retrofit CMM cabinet ECD2011-22

Typ obsahu: Stažení | Jazyk: English | Přípona souboru: pdf | Velikost souboru: 59 KB

Výrobní řady: CMM probes, software and retrofits

Mounting MCR20 onto the CMM

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 125 KB | Rozměry: 760 x 543 px

Výrobní řady: CMM probes, software and retrofits

MODUS 2 - CMM simulation speed

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : png | Velikost souboru: 81 KB | Rozměry: 836 x 300 px

Výrobní řady: CMM probes, software and retrofits

CMM dynamics effect on scanning

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 74 KB | Rozměry: 480 x 434 px

Výrobní řady: CMM probes, software and retrofits

CMM Cable Checker ECD2017-23

Typ obsahu: Stažení | Jazyk: English | Přípona souboru: pdf | Velikost souboru: 1 MB

Výrobní řady: CMM probes, software and retrofits

MODUS 2 - CMM library options_1

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : png | Velikost souboru: 93 KB | Rozměry: 888 x 483 px

Výrobní řady: CMM probes, software and retrofits

MODUS 2 - CMM library options_2

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : png | Velikost souboru: 61 KB | Rozměry: 645 x 349 px

Výrobní řady: CMM probes, software and retrofits

SPA2 to UCC2 emergency stop cable

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

This straight cable has a 9-pin D-type plug at end 'A' and a 25-pin D-type plug at end 'B'.

MM block front inspection with REVO-2 and SFP2

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 451 KB | Rozměry: 2000 x 3000 px

Výrobní řady: CMM probes, software and retrofits

MM block front inspection with the REVO 5-axis multi-sensor system's SFP2 surface finish probe on an AGILITY CMM - dark.

EV stator inspection with hemispherical head

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 567 KB | Rozměry: 2000 x 3000 px

Výrobní řady: CMM probes, software and retrofits

EV stator inspection with the REVO 5-axis multi-sensor system's RSP2 scanning probe and hemispherical head on an AGILITY CMM.

MODUS Planning suite – Curve Probe: path simulation

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 187 KB | Rozměry: 1920 x 1041 px

Výrobní řady: CMM probes, software and retrofits

MODUS Planning suite applications offer a a set of automated shortcuts to frequent challenges in part programming, maximising the efficiency of the REVO CMM system with easy to use specialised...

TURBOCAM "high fives" revolutionary five-axis measurement technology

Typ obsahu: Stažení | Jazyk: English | Přípona souboru: pdf | Velikost souboru: 2 MB

Výrobní řady: CMM probes, software and retrofits

Leader in five-axis turbomachinery production quickly adopts Renishaw's new REVO five-axis measurement system, gaining faster throughput, greater CMM utilization, and easier programming

TURBOCAM “high fives” revolutionary inspection technology

Typ obsahu: Stažení | Jazyk: English | Přípona souboru: doc | Velikost souboru: 156 KB

Výrobní řady: CMM probes, software and retrofits

Leader in five-axis turbomachinery production quickly adopts Renishaw's new REVO five-axis measurement system, gaining faster throughput, greater CMM utilization, and easier programming

PHC10-3 Probe Head Controller

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

PHC10-3 Probe Head Controller Rear panel layout Key Description 1 9-way D-type plug for PICS output 2 9-way D-type connector to HCU1 3 25-way D-type plug RS232 communications connector to CMM...

RS232 Setup

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

RS232 Setup RS232 connector pinouts The PHC10-3 communicates with the CMM computer via the RS232 cable as shown in the table below.

MM block top inspection with REVO-2 and SFP2

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 424 KB | Rozměry: 2000 x 1333 px

Výrobní řady: CMM probes, software and retrofits

MM block top inspection with the REVO 5-axis multi-sensor system's SFP2 surface finish probe on an AGILITY CMM - wide light.

MM block top inspection with REVO-2 and SFP2

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 407 KB | Rozměry: 2000 x 1333 px

Výrobní řady: CMM probes, software and retrofits

MM block top inspection with the REVO 5-axis multi-sensor system's SFP2 surface finish probe on an AGILITY CMM - wide dark.

EV stator inspection with REVO-2 and RVP

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 129 KB | Rozměry: 1021 x 681 px

Výrobní řady: Precision measurement and process control

EV stator inspection with the REVO 5-axis multi-sensor system's RVP vision probe on an AGILITY L 122410 CMM in situ.

EV stator inspection with REVO-2 and RVP

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 3 MB | Rozměry: 3840 x 2160 px

Výrobní řady: Precision measurement and process control

EV stator inspection with the REVO 5-axis multi-sensor system's RVP vision probe on an AGILITY L 122410 CMM in situ.

REVO tip datum artefact (TDA) - bed-mounted

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : png | Velikost souboru: 149 KB | Rozměry: 600 x 600 px

Výrobní řady: CMM probes, software and retrofits

Probe and stylus changes may lead to fractional variations in the alignment of a CMM system when compared with the original calibration.

REVO tip datum artifact (TDA)

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 637 KB | Rozměry: 2193 x 2192 px

Výrobní řady: CMM probes, software and retrofits

Probe and stylus changes may lead to fractional variations in the alignment of a CMM system when compared with the original calibration.

Evaluating the results

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

Evaluating the results 1.

REVO RSP3 3D scanning probes

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

REVO RSP3 3D scanning probes Extended warranty For peace of mind a 3-year warranty is available for your new CMM products during the first 3 months from purchase.

HR - UPOZORENJA

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

HR - UPOZORENJA SIGURNOSNA NAPOMENA Svaki ACR2 priključak sadrži komponente s oprugom koje mogu dovesti do uklještenja ako se uklone poklopci.

CZ - UPOZORNĚNÍ

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

CZ - UPOZORNĚNÍ Mezi pohyblivými součástmi a mezi pohyblivými a statickými součástmi hrozí nebezpečí přiskřípnutí.

Touch-trigger probe systems introduction

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

Touch-trigger probe systems introduction Co-ordinate measuring machines (CMMs) have evolved from their origins in simple layout machines and manually operated systems, to highly accurate, automated...

PHS1 troubleshooting

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

PHS1 troubleshooting NOTE: Due to the extent of the CMM manufacturer's system responsibility, the following is only a basic fault diagnosis.

UCC T3 PLUS

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 59 KB | Rozměry: 780 x 322 px

Výrobní řady: CMM probes, software and retrofits

Powerful 3-axis CMM controller featuring built-in standard touch-trigger and TP200 interface, PH10 PLUS head controller and thermal error compensation (TEC).

AGILITY S 796 with REVO-2

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 5 MB | Rozměry: 7680 x 4975 px

Výrobní řady: Precision measurement and process control

REVO-2 head and REVO 5-axis multi-sensor system's RSP2 scanning probe viewed through the holes in the AGILITY S 796 CMM.

AGILITY S 796 with REVO-2 - banner

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 90 KB | Rozměry: 1280 x 350 px

Výrobní řady: Precision measurement and process control

REVO-2 head and REVO 5-axis multi-sensor system's RSP2 scanning probe viewed through the holes in the AGILITY S 796 CMM.

Probe operation

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

Probe operation The probe has two normal operating states, armed or triggered.

MCG setting-up

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

MCG setting-up NOTE: It is recommended that when mounting the tower to the CMM table that the base of the tower is clamped on the central steel clamping ring.

MACH 2024

Typ obsahu: Webová stránka | Jazyk: English

MACH 2024 January 2024 Precision engineering and manufacturing technologies company, Renishaw, is exhibiting its extensive range of smart manufacturing technologies at this year's MACH exhibition...

PICS connection

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

PICS connection PICS interface configuration If the PHC10-3 is to be used in a PICS linked system, the PPOFF configuration is selected using switch 7.

RTP20 fault finding

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

RTP20 fault finding Unwanted triggering during probe or CMM movement Possible causes Remedy Trigger force too low / stylus configuration to heavy Use higher force module / reduce mass of stylus...

System connection

Typ obsahu: Webová stránka | Jazyk: English

Výrobní řady: CMM probes, software and retrofits

System connection The REVO-2 head and CMM system are operated through UCCserver which uses I++DME command protocol to communicate between the system application software and the UCC S5.

M6 plate, 19 mm x 600 mm x 600 mm

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 2 MB | Rozměry: 2500 x 2425 px

Výrobní řady: Fixtures

This M6 CMM precision ground aluminium base plate has multiple M6 threaded holes spaced at 12.5 mm intervals to increase the flexibility of your fixture.

M6 plate, 12.7 mm x 450 mm x 450 mm

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 1 MB | Rozměry: 2500 x 2500 px

Výrobní řady: Fixtures

This M6 CMM precision ground aluminium base plate has multiple M6 threaded holes spaced at 12.5 mm intervals to increase the flexibility of your fixture.

M6 plate, 12.7 mm x 450 mm x 450 mm (angled)

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 534 KB | Rozměry: 2500 x 1277 px

Výrobní řady: Fixtures

This M6 CMM precision ground aluminium base plate has multiple M6 threaded holes spaced at 12.5 mm intervals to increase the flexibility of your fixture.

RLE ISARA application

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 9 KB | Rozměry: 180 x 180 px

Výrobní řady: Interferometric laser encoders

RLE application, ISARA high accuracy CMM

RLE ISARA application

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 25 KB | Rozměry: 540 x 541 px

Výrobní řady: Interferometric laser encoders

RLE application, ISARA high accuracy CMM

Early literature

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 12 KB | Rozměry: 180 x 205 px

early literature,first probe,notsa cmm

Renishaw retrofit logo

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 67 KB | Rozměry: 600 x 100 px

Výrobní řady: CMM probes, software and retrofits

Logo for Renishaw's CMM retrofit service.

Early literature

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 41 KB | Rozměry: 540 x 615 px

early literature,first probe,notsa cmm

Early literature

Typ obsahu: Obrázek: | Jazyk: English | Přípona souboru : jpg | Velikost souboru: 725 KB | Rozměry: 1200 x 1366 px

early literature,first probe,notsa cmm