Filter by

Results found for Software

Laser software suite

laser software suite

CARTO Compensate

Compensate is the final stage in the CARTO software suite, allowing you to capture, analyse and compensate the errors in your machine.

CARTO Compensate

Compensate is the final stage in the CARTO software suite, allowing you to capture, analyse and compensate the errors in your machine.

CARTO 'Target-based mode'

CARTO 'Target-based mode' - intuitive software for quick data capture. Customisable part program generation, automatic sign detection, user friendly and customisable interface.

Video: Reduced build volume (RBV)

Reduced build volume (RBV) for Renishaw AM systems. For rapid material changeover; ideal for R&D. Use with QuantAM software for open access parameter development.

Engines and blades

We have decades of experience supporting the manufacture and maintenance of aero engines, delivering efficient, repeatable, traceable manufacturing processes for the most costly and...

Configurable environment

MODUS features a user-configurable Windows interface that can be tailored to suit the needs of the user.

3D Metalforge ventures out into metal additive manufacturing

3D Metalforge uses Renishaw's additive manufacturing systems and software to help select a future-proof additive manufacturing system for flexible, high-quality end-use part production.

Renishaw launches new line of products for industrial automation

Global engineering technologies company, Renishaw, is unveiling a newly developed product line specifically designed for the industrial automation market.

Equator™ 500 comparator gauge

The Equator 500 comparator gauge enables the gauging of larger parts, with a working volume of 500 mm in diameter, up to 400 mm in height and a payload capacity of 100 kg.

Powerful and intuitive machine tool probing software

A Brochure containing all machine tool probing software and complimentary machine tool calibration software solutions offered by Renishaw.

Graduate Manufacturing Software Engineer

Graduate Manufacturing Software Engineer

WiRE1 About software

WIRE1 software version example

Graduate manufacturing software engineer

Graduate manufacturing software engineer

Renishaw employee using software

Renishaw employee using software

Video: Reduced build volume (RBV)

English and German. Reduced build volume (RBV) for Renishaw AM systems. For rapid material changeover; ideal for R&D. Use with QuantAM software for open access parameter development.

Toolsetting software icon

Tool setting software for machine tools

Productivity+™ software

Productivity+™ software tool and part setting

Measurement software button

Screen view of measurement software

Raman software training

A researcher uses Renishaw’s WiRE software to process and analyse Raman spectra.

Metrolog II software

Metrolog II software Metrologic UCC

Raman software training

A researcher uses Renishaw’s WiRE software to process and analyse Raman spectra.

InfiniAM Spectral, laser and melt pool monitoring

InfiniAM Spectral is Renishaw's beam path process monitoring solution. Demonstration of the software to visualise data in 2D and 3D, and overview of the hardware used to collect the data.

Signum software

signum,software,angle encoder

Software development

r&d,software development

Software maintenance

Optional software maintenance programme

Software development

r&d,software development

Signum software

signum,software,angle encoder

Display software

Display software

SiGNUM software

SiGNUM software, angle, linear encoders

FixtureBuilder software

This document provides the answers to the frequently asked questions regarding the software download, installation and license activation.

SiGNUM software

signum,software,angle encoder

SiGNUM software

signum,software,angle encoder

Software development

r&d,software development

Software development

r&d,software development

FixtureBuilder software

FixtureBuilder is a 3D software package designed to allow the creation and documentation of metrology fixturing set-ups. It can also be used to assist with offline programming.

FixtureBuilder software

FixtureBuilder is a 3D-modelling software package designed to allow the off-line creation and documentation of fixturing set-ups.

Common Productivity+™ topics

Common Productivity+™ topics This page provides assistance on commonly asked questions concerning Productivity+™.

Work experience weeks

For students in years 10 to 13 at schools throughout Gloucestershire, South Gloucestershire, Bristol and South Wales, Renishaw's work experience weeks provide the ideal opportunity to discover what...

StreamHR Rapide - nasal spray

Using a Renishaw inVia confocal Raman microscope and WiRE™ software to image a drop of nasal medication. The image build up is shown at true data collection speed using StreamHR Rapide.

UCC DMT introduction

UCC DMT introduction Software setup Error mapping is carried out through UCCassist-2 using the sequence player.

Manual control systems description

Manual control systems description NOTE: The MCUlite-2 is not compatible with UCC1.

Bespoke bike maker harnesses additive manufacturing

Maintaining the consistency and quality of hand-made titanium bicycle components isn’t easy, it takes consummate skill, care and time.

Return to zero

Return to zero The probe has a nominal absolute centre position where the functions of stylus configuration and probe orientation cause it to rest.

Software nav button ipad app

Software nav button ipad app

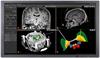

Neuroinspire neurosurgical planning software

The neuroinspire™ surgical planning software provides the tools that can assist you with the planning of most stereotactic procedures.

1st Class Honours for Renishaw Software Apprentices

Two Renishaw Software Engineers have graduated with 1st Class Honours in Systems Engineering after completing the Renishaw software apprenticeship scheme.

WiRE software training banner

WiRE software training on laptop

Equator™ Software Suite 1.x

Equator Software Suite user guide

SEEG procedure using the neuromate stereotactic robot

Overview of the Renishaw neuromate® stereotactic robot and the neuroinspire™ software being used for electrode planning and placement in stereoelectroencephalography (SEEG) procedures.