Filter by

Results found for SiGNUM™ software

Scania – where machine tool maintenance is an investment, not a cost

Dynamate AB, the plant maintenance company for world leading truck manufacturer Scania, has implemented one of the most comprehensive and well-structured maintenance strategies in it's industry.

Gear manufacturer achieves consistent quality with automated robot cell

Gear and gearbox manufacturer Katsa Oy commissioned Flexmill Oy to design and build a robotised cell to finishmachine and deburr gears ranging in size from 50 mm to 1.

CENTRUM™ discs with ATOM DX™ (white background)

Media image

BB5 HPS v5.08 SCREEN B

ISO analysis screen shot for V5.08 (Vista compatible) software

Probing glossary and terminology

Probing glossary and terminology Improve my process links Why probe? When to probe? How can probing help? Application stories and news Case briefs Probing glossary Technical papers Generic and...

UCC T5 PH20 CMM controller installation guide

UCC T5 PH20 CMM controller installation guide Click here if you prefer to download a PDF version of this guide: NOTE: Please use the left-hand navigation to view this complete document.

MCU references and associated documents

MCU references and associated documents It is recommended that the following documentation be referred to when installing an MCU.

News, case briefs and technical papers

Use the links below to see the actual value delivered through the use of machine tool probing systems.

Internal combustion engine manufacturing

As a manufacturer itself, Renishaw understands that to truly transform operations, companies also need the ability to identify and control sources of process variation before, during and after machining.

Incremental encoders help optimise the fuel efficiency of aero-engines

HAESL (Hong Kong Aero Engine Services Limited) believes that it has successfully solved this challenge by incorporating Renishaw's TONiC incremental linear and rotary (angle) encoders within its new...

REVO valve seat and guide measurement

REVO® and Renishaw's 5-axis technology dramatically increase throughput in this challenging application – data collection process takes approximately 20 seconds.

Establishing a docking position for TP20 modules

Establishing a docking position for TP20 modules This section describes how to establish the docking position for the combination of a TM25-20, a TP20 module and a stylus.

Aerospace case study

Aerospace case study APEXBlade is a package designed to greatly simplify continuous 5-axis scan path production.

Datuming SCR600

Datuming SCR600 Software alignment for the SCR600 This section describes the suggested software alignment routine to find the positions of the SCR600 ports.

Wireless QC20-W ballbar loses cable and gains support

NC Service, a Swedish machine tool calibration and maintenance company, who work with key CNC machine users, was one of the first users worldwide to take delivery of Renishaw's QC20-W ballbar.

Mori Seiki uses Renishaw ballbar to give highest standard of customer service

Mori Seiki Group is acknowledged as one of the world’s leading designers and manufacturers of high specification machine tools, having delivered more than 185,000 units worldwide since its foundation...

Metrology fixtures for vision systems

Renishaw's fixtures for vision systems include acrylic base plates allowing for back lighting for clear and clean inspection. Discover more and buy online today!

Renishaw CNC Reporter

Renishaw CNC Reporter is a software package designed to display and process inspection results from Renishaw probing software.

Renishaw healthcare products collage

Collage of Renishaw healthcare products including Dental scanner, mill and software, dental bridge, molecular diagnostics hardware, neuro implant, neuro robot, Neuro Inspire software, AFM raman, SCA...

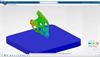

SIMULIA Distortion Checker

Screen shot of a bracket in Simulia Distortion Checker software

Renishaw previews QuantAM Dental at IDS

Renishaw previews QuantAM Dental software for additive manufacturing at IDS

Ballbar5 HPS v5.08 machine tool analysis screen shot

Renishaw analysis screen shot BB5 version 5.08 (VISTA COMPATIBLE SOFTWARE)

Encoder Product Configurator Splash Screen

A splash screen image for the Encoder Product Configurator software.

Ballbar5 HPS v5.08 machine tool analysis screen shot

Renishaw analysis screen shot BB5 version 5.08 (VISTA COMPATIBLE SOFTWARE)

Tracecut in use

View of tracecut software being used in conjunction with Cyclone

DMIS program - RackSetup

DMIS programs for the RackSetup procedure for Software Suite 1.4

Renishaw to launch new AM system at Formnext 2024

Renishaw will launch the latest offering for its RenAM 500 series of metal additive manufacturing (AM) systems at Formnext 2024, in Frankfurt, Germany, from November 19 to 22.

Renishaw helps Irish Manufacturing Research (IMR) to advance aerospace optics manufacturing

Renishaw has collaborated with Irish Manufacturing Research (IMR) to support groundbreaking research into additive manufacturing (AM) for novel aerospace materials.

Free 30-day trial for new Renishaw touch probe software

Renishaw is offering a free 30-day trial of its latest version of Productivity+, a powerful software package that simplifies the generation of touch probe routines for CNC machine tools.

M6 QuickLoad Plate, 12.7 mm × 300 mm × 300 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

M6 QuickLoad Plate, 12.7 mm × 150 mm × 150 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

M6 QuickLoad Plate, 12.7 mm × 300 mm × 300 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

Encoders accelerate PCB impedance verification

Volume manufacturing of high frequency electronic products requires high-performance PCB impedance measurement machinery capable of reliably verifying that actual production outcomes meet with...

Encoders accelerate PCB impedance verification

Volume manufacturing of high frequency electronic products requires high-performance PCB impedance measurement machinery capable of reliably verifying that actual production outcomes meet with...

M6 QuickLoad Plate, 12.7 mm × 300 mm × 300 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

M6 QuickLoad Plate, 12.7 mm × 450 mm × 450 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

M6 QuickLoad Plate, 12.7 mm × 450 mm × 450 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

M6 QuickLoad Plate, 12.7 mm × 150 mm × 150 mm

The Renishaw QuickLoad plates have been specifically designed for use with the Renishaw QuickLoad™ rail.

How to build an automated robotic CNC manufacturing cell using Equator for process control

An introduction on how to automate your CNC manufacturing process.

Arcus Technology's DMX-K-SA-11 stepper motor uses Renishaw's AM256 encoder chip

DMX-K-SA-11 stepper motor uses Renishaw's AM256 magnetic encoder chip for real-time position verification

Arcus Technology’s DMX-K-SA-11 stepper motor uses Renishaw’s AM256 encoder chip

DMX-K-SA-11 stepper motor uses Renishaw's AM256 magnetic encoder chip for real-time position verification

RMP600 and NC4

Transform your manufacturing image.

XR20 rotary axis calibrator

The XR20 rotary axis calibrator works in conjunction with XL-80 and XM-60 laser systems providing highly accurate, repeatable rotary axis calibration for stages, jigs and machine tools.