Filter by

Results found for SiGNUM™ software

Ø19 mm x 25 mm spring pusher standoff clamp with M6 thread

This spring pusher standoff clamp is designed to fixture parts in tight spaces, removing the need for tension clamps.

Ø12 mm x 10 mm spring pusher standoff clamp

The spring pusher standoff clamp is designed to fixture parts in tight spaces, removing the need for tension clamps.

Renishaw launches first functionally safe absolute open optical encoder

Renishaw builds on its existing functionally safe (FS) portfolio by introducing the RESOLUTE™ FS absolute open-optical encoder for both linear and rotary axis applications.

Ø12 mm x 10 mm spring pusher standoff clamp

The spring pusher standoff clamp is designed to fixture parts in tight spaces, removing the need for tension clamps.

RLS launches a 20 bit absolute magnetic ring encoder

Renishaw’s associate company RLS announces the launch of the new AksIM™ true-absolute magnetic rotary encoder for embedded OEM motion control applications.

ALIO Industries depend on TONiC optical encoders

In ALIO's tiny world of nano-motion systems, Renishaw encoders provide large performance and cost advantages.

Optical encoders compliance information

Select the required compliance data relating to EU / UK Declaration of Conformity, RoHS, WEEE, Material Safety, ISO 9001, Conflict Minerals, REACH, Green productivity and Functional Safety.

Header - Software

HR website pages

Powerful software

Image of web page

Software development

r&d,product development

BB5 HPS v5.08 SCREEN B

ISO analysis screen shot for V5.08 (Vista compatible) software

CENTRUM™ discs with ATOM DX™ (white background)

Media image

12.7 mm x 50 mm x 75 mm adjustable angle plate

This adjustable angle plate is ideal for holding components at an angle.

12.7 mm x 50 mm x 75 mm adjustable angle plate

This adjustable angle plate is ideal for holding components at an angle.

12 mm × 50 mm × 75 mm adjustable angle plate with M4 thread

This adjustable angle plate is ideal for holding components at an angle.

Single-ended LVTTL to RS422 differential converter

For use with AksIM™ MBA-type encoders with BiSS or SSI communication interfaces to allow connection to RS422 compatible controllers or encoder interfaces.

12.7 mm × 50 mm × 75 mm adjustable angle plate with M6 thread

This adjustable angle plate is ideal for holding components at an angle.

12 mm × 50 mm × 75 mm adjustable angle plate with M4 thread

This adjustable angle plate is ideal for holding components at an angle.

12.7 mm × 50 mm × 75 mm adjustable angle plate with M6 thread

This adjustable angle plate is ideal for holding components at an angle.

Calibration application notes

Application notes providing information and support for Renishaw laser measurement and ballbar products.

Scania – where machine tool maintenance is an investment, not a cost

Dynamate AB, the plant maintenance company for world leading truck manufacturer Scania, has implemented one of the most comprehensive and well-structured maintenance strategies in it's industry.

Gear manufacturer achieves consistent quality with automated robot cell

Gear and gearbox manufacturer Katsa Oy commissioned Flexmill Oy to design and build a robotised cell to finishmachine and deburr gears ranging in size from 50 mm to 1.

Probing glossary and terminology

Probing glossary and terminology Improve my process links Why probe? When to probe? How can probing help? Application stories and news Case briefs Probing glossary Technical papers Generic and...

UCC T5 PH20 CMM controller installation guide

UCC T5 PH20 CMM controller installation guide Click here if you prefer to download a PDF version of this guide: NOTE: Please use the left-hand navigation to view this complete document.

News, case briefs and technical papers

Use the links below to see the actual value delivered through the use of machine tool probing systems.

MCU references and associated documents

MCU references and associated documents It is recommended that the following documentation be referred to when installing an MCU.

Renishaw CNC Reporter

Renishaw CNC Reporter is a software package designed to display and process inspection results from Renishaw probing software.

Renishaw healthcare products collage

Collage of Renishaw healthcare products including Dental scanner, mill and software, dental bridge, molecular diagnostics hardware, neuro implant, neuro robot, Neuro Inspire software, AFM raman, SCA...

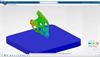

SIMULIA Distortion Checker

Screen shot of a bracket in Simulia Distortion Checker software

Renishaw previews QuantAM Dental at IDS

Renishaw previews QuantAM Dental software for additive manufacturing at IDS

Ballbar5 HPS v5.08 machine tool analysis screen shot

Renishaw analysis screen shot BB5 version 5.08 (VISTA COMPATIBLE SOFTWARE)

Encoder Product Configurator Splash Screen

A splash screen image for the Encoder Product Configurator software.

Ballbar5 HPS v5.08 machine tool analysis screen shot

Renishaw analysis screen shot BB5 version 5.08 (VISTA COMPATIBLE SOFTWARE)

Tracecut in use

View of tracecut software being used in conjunction with Cyclone

DMIS program - RackSetup

DMIS programs for the RackSetup procedure for Software Suite 1.4

Aerospace case study

Aerospace case study APEXBlade is a package designed to greatly simplify continuous 5-axis scan path production.