Filter by

Results found for renishaw

Renishaw montage

product montage

Renishaw retrofit

Transform your old CMM with a new lease of life, speed and capability

Renishaw Seminar

cmm,scanning,seminar

Renishaw apprentices

The engineering apprenticeships provide a paid opportunity for students to gain nationally recognised qualifications.

Renishaw Seminar

machine tool,probing,seminar

Renishaw Seminar

cmm,scanning,seminar

Renishaw encoder

Encoder

Renishaw Seminar

performance check,seminar

On-machine scanning probes with SPRINT™ technology

High-speed, high-accuracy, on-machine scanning probes with SPRINT™ technology.

Video:AgustaWestlands Wildcat Supplier case study

To help win and maintain its preferred supplier status to one of the world’s top aerospace manufacturing companies, Tods Aerospace Ltd invested in a CMS five-axis router, a Renishaw RMP600 wireless...

SP600 stylus changing provides overtravel protection

Detachable stylus modules provide a valuable safety feature on Renishaw scanning probes, preventing the build-up of excessive forces in most accidental collisions.

DS20 Open

Renishaw DS20 dental scanner - Open

Manual tool length and diameter setting: Fanuc GUI

Manual tool length and diameter setting screenshot from the Renishaw Fanuc GUI

Encouraging the next generation of female engineers

Taking place annually on 23 June, International Women in Engineering Day is an awareness campaign to raise the profile of women in engineering and focus attention on the amazing career opportunities...

Jens Bech Jensen, VD, Fron-Tech

Renishaw, ett av världens ledande företag inom precisionsteknik och vetenskapsteknologi, har utsett Fron-Tech ApS — en distributör av Renishaw-produkter, Montech-komponenter inom automation och...

‘Employee perspectives’: An insight into engineering careers

There is not one singular blueprint that can lead to a career in the engineering industry.

Easyset probe stylus offsets calibration: Okuma mill GUI

Easyset probe stylus offsets calibration screenshot from the Renishaw Okuma mill GUI

Multi tool length setting defined order: Fanuc GUI

Multi tool length setting in a user defined order screenshot from the Renishaw Fanuc GUI

Innovation Matters 2022

Renishaw’s annual company magazine.

Pioneering additive manufacturing reshapes patient’s face

Additive manufacturing (3D printing) is changing and improving many traditional industries and processes.

Custom solutions for CNC machine tools

Custom solutions for CNC machine tools Custom inspection and tool setting arms Arms can be designed to suit a variety of applications, from large twin probe arms for tool setting on lathes, to...

Cable and connector specification

Cable and connector specification Input pin connections The pin connections for the 9-way ‘D' type input plug are: Pin Function 1 STOP 2 PPOFF 3 0 V 4 LED anode * 5 Probe signal...

Metal 3D printing

Additive manufacturing, also called 3D printing, is a process used to create three-dimensional parts from a digital file.

Renishaw colleagues at the Girls into Technology event at SGS Berkeley Green UTC

Global engineering technologies company, Renishaw, ran two workshops at a Girls into Technology event held at SGS Berkeley Green UTC, a university technical college in Gloucestershire, UK.

Simufact and Renishaw collaborate to streamline additive manufacturing simulation and build file preparation

Global engineering company, Renishaw, is collaborating with Simufact to enhance the success of laser powder bed fusion (LPBF) builds through accurate simulation and streamlined additive manufacturing...

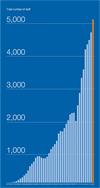

Chart showing average headcount for the Renishaw group up to the year 2020

Chart showing average headcount for the Renishaw group up to the year 2020

Renishaw announces completion of the main part of a multi-centre clinical trial

Global engineering technologies company, Renishaw, announces that its award-winning intraparenchymal drug delivery device, has played a critical role in a joint Phase 1-2 clinical study with Herantis...

In-process inspection with Renishaw OMP600 machine tool probe

An image showing in-process inspection using a Renishaw OMP600 machine tool probe

Renishaw and IDEKO inaugurate a new R&D facility in the Basque Country

Renishaw and IDEKO inaugurate a new R&D facility in the Basque Country

Renishaw partners with the Empowered Employers campaign to improve the Disability Employment Gap

To help create an inclusive and diverse business community, global engineering technologies company, Renishaw, has partnered with the Empowered Employers campaign, led by Barnwood Trust, a...

Students from Al-Ashraf Secondary School for Girls at the Renishaw STEM Centre

Students from Al-Ashraf Secondary School for Girls at the Renishaw STEM Centre

Chart showing average headcount for the Renishaw group up to the year 2019

Chart showing average headcount for the Renishaw group up to the year 2019

Chart showing revenue for the Renishaw group up to the year 2021

Chart showing revenue for the Renishaw group up to the year 2020 (jpg)

Chart showing average headcount for the Renishaw group up to the year 2021

Chart showing average headcount for the Renishaw group up to the year 2021

Chart showing average headcount for the Renishaw group up to the year 2019

Chart showing average headcount for the Renishaw group up to the year 2019

Renishaw additive manufacturing helps British cyclist Matthew Richardson beat 200m world record @SWpix

Renishaw additive manufacturing helps British cyclist Matthew Richardson beat 200m world record @SWpix

Byran Austin and Rupert Jones from Renishaw, with Vaughan Gething, Minister for Economy

Byran Austin and Rupert Jones from Renishaw, with Vaughan Gething, Minister for Economy

Machine tool probing increases productivity for Australian machine shop

When Australia-based machine shop, Hammond Engineering, found that manually setting workpiece positions was time consuming and difficult to repeat, it looked to the potential of on-machine probing.

Renishaw gender pay gap report 2019

This document summarises Renishaw’s Gender Pay Gap in the UK as at April 2018.

Renishaw supports Future Brunels educational programme

Leading engineering and scientific technology company, Renishaw, supports the pioneering Future Brunels programme developed by the ss Great Britain Trust.

Renishaw enters the CMM retrofit market

Renishaw assembles the technol