Filter by

Results found for Software

Using the SP600, SP600M and SP600Q

Using the SP600, SP600M and SP600Q Qualification The SP600M family of probes require qualification before they are able to give accurate positional data.

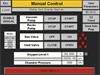

UCC MMI-2 troubleshooting

UCC MMI-2 troubleshooting Fatal faults Situations can occur that make it inadvisable or dangerous to continue using the CMM system.

FORTiS-S™ FS enclosed absolute encoder

Need functional safety encoders for machine tools? Renishaw’s FORTiS-S™ FS encoder series is a next generation linear enclosed absolute encoder with a range of innovative features.

Autodesk Technology Centres ensure precision with QC20 ballbar testing

Autodesk’s teams successfully calibrated equipment using Renishaw’s QC20 ballbar, ensuring their machines are performing within specification.

ReniKey macro for Okuma controls

ReniKey software has been designed to simplify the partnering process between an RMI-Q interface and a Renishaw radio probe.

Support/knowledgebase material: CAD view window appears red at start-up

Some users of Productivity+™ Active Editor Pro have reported instances where the CAD view window within the software appears red when the program is opened.

PBC-1209 - UCC2 - compliance with Windows Vista

All future issues of UCC software will be compliant with Microsoft Windows Vista® and in order for a UCC2 controller to work with Vista we have to make a small change to the firmware of the UCC2.

Renishaw and Identify3D collaborate to enable secure digital manufacturing

Renishaw, a world leader in metrology and additive manufacturing (AM) technologies, and Identify3D, a leader in software for the digital supply chain, are pleased to announce a collaboration to offer...

QC20-W on machine tool with software

Banner image for Ballbar 20 web page

Process Monitor remastering software for Equator™

Process monitor window

RCU CS v2.0.5

RCU CS is the RCU10 configuration software.

HS20 to RCU10 signal strength cable

Laser signal strength monitoring functionality through the RCU-CS software (version 2.

Open CAD/CAM systems for digital dentistry

The digitisation of dentistry and dental technology has helped to realise real life economic and technical gains.

QC20 volumetric testing using a single program

This application note explains how to create a single part program using Ballbar 20 software which enables the QC20 ballbar user to carry out three plane testing without the need to remove the...

Renishaw unveils Inspection Plus with SupaTouch optimisation delivering intelligent speed

Renishaw, a market-leading engineering technologies company, will introduce Inspection Plus with SupaTouch optimisation at EMO 2015, Milan, Italy (5th-10th October, hall 5 stand D15).

LaserXL 'freezing' patch

This patch fixes problems on some later PC’s where the software can freeze, particularly during datums, unit change and manual data capture.

Advanced Diagnostic Tool ADTi-100

The ADTi-100 (A-6195-0100) is used in conjunction with a PC* running the ADT View software†.

Motor connectors

Motor connectors DC motor connection card termination Each DC motor connection card presents a 7W2 connector for connection of a CMM motor to the SPA2-2, as shown below: There are seven...

neurolocate™ frameless patient registration module

neurolocate™ frameless patient registration module Advantages Quote quote title Highlights The neurolocate registration module provides a new frameless registration system for the neuromate...

Acquisition mode select register (base address + 12)

Acquisition mode select register (base address + 12) This read/write register allows the software to set the AC3 to the required acquisition mode, with a selected interrupt (if required).

Establishing a docking position for SM25 and TM25-20 modules

Establishing a docking position for SM25 and TM25-20 modules This section describes how to manually position the probe body and module to define the module docking position of the desired port.

Pump manufacturer extends the life of their machine tools and reduces downtime by 10%

The Renishaw QC20-W ballbar system is widely recognised as a preventative maintenance tool for new and installed machines.