Filter by

Results found for “Manual setting and NC programming is needless torture for machine operators…”

In718-0405 powder for additive manufacturing

Data sheet for metal powders for additive manufacturing supplied by Renishaw.

FR - Sécurité

FR - Sécurité Sortie laser Sortie maximale : < 5 mW Durée de l'impulsion : onde continue Longueur d'ondes : 670 nm Divergence faisceau : 2 mrad Le corps du SFP1 renferme des sources laser...

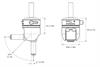

TONiC™ encoder system

Renishaw’s TONiC™ series represents a new generation of super-compact encoders, designed for highly-dynamic precision motion systems, bringing higher accuracy, speed and greater reliability to a wide...

Multiple component 3D Raman volume image of a glioma cell.

Multiple component 3D Raman volume image of a glioma cell.

Business Minister Mark Prisk with Chris Pockett & other exhibitors

L-R: Chris Pockett - Renishaw, Dr Damien Cleugh - Mazak, Robert Johnson - Craftsman Tools Ltd and John Kavanagh - JCB with Business Minister Mark Prisk (in the JCB cab) at the Department for Busine...

Renishaw staff running hands on activities are the engineering open house 2018

On August 3rd, 2018, global engineering technologies company Renishaw hosted 500 young people and their parents at its Gloucestershire headquarters for an open house.

Renishaw hosts inaugural South Wales Greenpower event

Global engineering company Renishaw hosted the first South Wales Greenpower event at its Miskin site on July 2nd, 2016, which saw teams competing in the IET Formula Goblin category for primary school...

X marks the spot - find the ideal process parameters for your metal AM parts

Marc Saunders, Director of AM Applications at Renishaw, explains how to find the ideal process parameters for your metal additive manufactured (AM) parts.

Renishaw joins project to automate additive manufacturing post-processing

Global engineering technologies company Renishaw is collaborating with UK start-up business Additive Automations, as part of a project to automate metal additive manufacturing (AM) post-processing,...

MR Bonded Radial Incremental Magnetic Rings

The robust RLS radial magnetic incremental rings consist of an elastoferrite layer firmly bonded on a stainless steel hub.

Inspection support and training

Image of a training session for inspection modules.

A-9920-0330 - Battery Li-polymer 3.7V

High-power rechargeable lithium battery for use with XR20 rotary axis calibrator, XM-60 or XM-600 multi-axis calibrator.

A-5991-0112 - OMM-2C mounting screw

Replacement OMM-2C mounting screw. For use with the integral air blast version of the OMM-2C (A-5991-0005).

Valve seat and guide measurement

REVO® valve seat and guide measurement and analysis

R-TB-751-20 - 0.75 in × 0.75 in × 2.75 in tower block with 1/4-20 thread

For use with towers, to mount other fixturing components at planes of 90° to standard mounting holes

A-6551-0051 - RMI-QE interface (30 m)

The RMI-QE includes a 30 m cable and tool kit.

A-5555-0226 - M5 to M2 stainless steel adaptor, L 10 mm, for ZEISS applications

Stylus adaptors are designed to allow styli with different thread sizes to be built into stylus configurations.

A-5555-0306 - M2 to M3 stainless steel adaptor, L 5 mm, for ZEISS applications

Stylus adaptors are designed to allow styli with different thread sizes to be built into stylus configurations.

A-5555-2457 - M2 to M3 stainless steel adaptor, L 7 mm, for ZEISS applications

Stylus adaptors are designed to allow styli with different thread sizes to be built into stylus configurations.

Cable assembly for MA2 probe holder

Curly cable assembly for MA2 probe holder. Used for hard-wired transmission

CNC machined needles of 60 μm diameter at EMO 2023

Image for website

Defoamer for Ruwac vacuums

Defoamer used in the Ruwac unit for processing Aluminium powder.

Motion stage for synchrotron mirror

Image for website

R-TC-300190-4 - 305 mm × 190 mm × 25 mm small component tray to hold M4 components

R-TC-300190-4 305 mm × 190 mm × 25 mm small component tray to hold M4 components Small component tray to hold and organise fixturing components.

Welcome to Renishaw AM Solutions Centre - Ontario, Canada

Take a look at Renishaw Canada's subsidiary and its metal 3D printing Solutions Centre in Ontario, Canada.

CMM inspection of a hairpin stator using the REVO® multi-sensor system

Fast and automated CMM inspection of a hairpin stator using the REVO® multi-sensor system.

OMM-2

Optical machine module (receiver)

XL-80 application

Machine tool positioning errors

Hamilton engine

machine tool,hamilton,engine

HPMA

machine tools,hpma,lathes

Renishaw Seminar

machine tool,probing,seminar

HPMA

machine tools,hpma,lathes

Cyclone product Training

digitising machine cyclone training

Operator's guide: MP700 probe system

MP700 machine spindle probe

Hamilton logo

machine tool,hamilton,logo

XL-80 application

Machine tool positioning errors

Renscan

digitisng,renscan,milling machine

Renishaw Seminar

machine tool,probing,seminar

Target

machine tool,process capability

Locating the stylus ball between the stylus guide rods

MCG machine checking gauge

IMM

Inductive transmission – machine module

Ramtic

Ramtic carousel machine shop

Renscan

digitising,renscan,milling machine

Hamilton benefits

machine tool,hamilton,benefits

XL-80 application with XR20-W

The XR20-W rotary axis calibrator used in conjunction with XL-80 laser to provide ±1 arc sec measurement accuracy.