Filter by

Results found for incise™ dental CAD/masters/

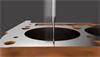

On-machine scanning - Surface Condition

Using the Renishaw OSP60 scanning probe with SPRINT™ technology to monitor the effects of worn or damaged tools on flat sealing faces with SupaScan or the Productivity+™ Scanning Suite.

R-CT-40-70-8 - 36.2 mm tension clamp with 68.1 mm post and M8 thread

This tension clamp is used for the quick and easy clamping of parts onto CMMs and the Equator™ gauging systems.

RESM40USA200 - RESM incremental tapered internal diameter ring (200 mm diameter, 40 μm pitch, one reference mark (standard))

RESM40USA200 is a 200 mm diameter, 40 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA150 - RESM incremental tapered internal diameter ring (150 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA150 is a 150 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA115 - RESM incremental tapered internal diameter ring (115 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA115 is a 115 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM40USA052 - RESM incremental tapered internal diameter ring (52 mm diameter, 40 μm pitch, one reference mark (standard))

RESM40USA052 is a 52 mm diameter, 40 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM40USA100 - RESM incremental tapered internal diameter ring (100 mm diameter, 40 μm pitch, one reference mark (standard))

RESM40USA100 is a 100 mm diameter, 40 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA075 - RESM incremental tapered internal diameter ring (75 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA075 is a 75 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM40USA150 - RESM incremental tapered internal diameter ring (150 mm diameter, 40 μm pitch, one reference mark (standard))

RESM40USA150 is a 150 mm diameter, 40 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA100 - RESM incremental tapered internal diameter ring (100 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA100 is a 100 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA052 - RESM incremental tapered internal diameter ring (52 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA052 is a 52 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM20USA200 - RESM incremental tapered internal diameter ring (200 mm diameter, 20 μm pitch, one reference mark (standard))

RESM20USA200 is a 200 mm diameter, 20 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

RESM40USA075 - RESM incremental tapered internal diameter ring (75 mm diameter, 40 μm pitch, one reference mark (standard))

RESM40USA075 is a 75 mm diameter, 40 µm pitch, stainless steel encoder ring incorporating an IN-TRAC™ optical reference mark.

Calibration CAD models

Calibration CAD models Contact our sales team today Get in contact with your local office to find out more information and speak to an expert.

LMT LAB DAY banner 2019

Renishaw is delighted to be taking part in LMT labday

Head of Industrial Drives at TQ-RoboDrive

Ulrich Kerber highlights the important role played by the RLS AksIM™ magnetic absolute encoder in robot drive applications.

A-5925-0200 - Equator™ gauge checker kit

The gauge checker kit is used as a quick health check to ensure that the Equator is working as well today as the day it was manufactured.

Laser encoder CAD models

Laser encoder CAD models RLE CAD models HS20 CAD models Air temperature sensor Material temperature sensor 15 mm DI periscope assembly Mirror mount kit RCU10 single axis compensator RLD detector...

Functional Safety (FS) encoder downloads

Download technical literature about the Renishaw Functional Safety incremental and absolute encoder series below.

R-CT-40-30-6 - 36.2 mm tension clamp with 30.0 mm post and M6 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

R-CT-40-70-6 - 36.2 mm tension clamp with 68.1 mm post and M6 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

R-CT-64-70-6 - 57.5 mm tension clamp with 68.1 mm post and M6 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

R-CT-95-83-6 - 87.7 mm tension clamp with 82.8 mm post and M6 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

R-CT-40-25-4 - 36.2 mm tension clamp with 25.0 mm post and M4 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

Image of DS10, right hand view

Image of DS10, right hand view

On-machine scanning - Adaptive machining

Using the Renishaw OSP60 scanning probe with SPRINT™ technology to do adaptive machining of variable 2D profile parts such as pump housings made from castings, using the Productivity+™ Adaptive Cut Toolkit.

Data sheets - Gauging products

Data sheets - Gauging products Browse documents Equator™ Auto Transfer System - EQ-ATS For EQ300 Plates Equator™ Auto Transfer System - EQ-ATS For EQ500 Plates EQ-ATS 300 tile hole positions EQ-...

R-CT-160-275-20 - 1.43 in tension clamp with 2.76 in post and 1/-20 thread

This tension clamp is used for the quick and easy clamping of parts onto CMM, Equator™, vision and multi-sensor machines.

Introducing the Advanced Diagnostic Tool, ADTi-100 and ADT View software

The QUANTiC™, VIONiC™ and ATOM DX™ series of incremental encoders are quick and easy to install and calibrate without the need for additional tools.

Productivity+™ – PC-based probe software for machining centres

PC-based probing software solution for machining centres, enabling sophisticated process control and adaptive machining.

R-CT-160-125-20 - 1.43 in tension clamp with 1.26 in post and 1/4 20 thread

This tension clamp is used for the quick and easy clamping of parts onto CMMs, Vision and the Equator™ gauging systems.

R-CT-250-275-20 - 2.26 in tension clamp with 2.76 in post and 1/4-20 thread

This tension clamp is used for the quick and easy clamping of parts onto CMMs, Vision and the Equator™ gauging systems.

R-CT-375-325-20 - 3.45 in tension clamp with 3.26 in post and 1/4 20 thread

This tension clamp is used for the quick and easy clamping of parts onto CMMs, Vision and the Equator™ gauging systems.

Optical encoders data sheets

Optical encoders data sheets Diagnostic tools Open optical encoders Enclosed optical encoders ATOM™ incremental encoders TONiC™ incremental encoders VIONiC™ incremental encoders RESOLUTE™...

LaserAbutments™

Supplied with each LaserAbutment, the instructions for use provide essential information including product indications, contraindications and specific procedures.

OPTiMUM™ diamond stylus scanning an aluminium Cosworth V10 engine block with a steel cylinder lining

Application image: OPTiMUM™ diamond stylus scanning an aluminium Cosworth V10 engine block with a steel cylinder lining

A-5504-2081 - Equator™ styli storage box only

A protective case with specially designed inserts for safe and clean storage of styli with space for up to six assembled stylus tools.

LMT labday Landing page banner

Banner image for LMT labday

LMT labday Landing page banner

Banner image for LMT labday

FORTiS™ enclosed encoder vibration testing

Vibration can be an issue for positional stability when cutting hard metals.

Automation and process control for Equator™ comparator gauges

Equator gauging hardware and software has been designed from the outset to be equally suited to manual or automated operation.

Chemometric Raman imaging with the Empty Modelling™ method

Find out which chemicals or species are present in your sample with Renishaw’s patented Empty modelling technique for the analysis of Raman data

Support/knowledgebase material: Spindle probe calibration

Calibration is the basis for all measurement data and must be performed before running any Productivity+™ cycles.

SOLPOWER rotary tables turn on RESOLUTE™ encoders

SOLPOWER, established in 1995, is a Taiwanese manufacturer of machine tool components such as Direct-Drive (DD) rotary tables, integrated spindle motors and linear motors.

Legacy REVO® measuring blisk

Banner image of legacy REVO® measuring blisk (Renscan5™).

Legacy REVO® measuring blisk

Thumbnail image of legacy REVO® measuring blisk (Renscan5™).

Improving machine tool accuracy with Renishaw FORTiS™ encoders and laser calibration systems

Renishaw’s products help HEAKE machine tools to produce consistently high-quality parts.

R-MV-19-6 - Ø19.1 mm × 25.0 mm V magnet with M6 thread

This V magnet is ideal for holding ferrous cylindrical workpieces and tubing. It is recommended for use on CMMs and the Equator™ gauging system.

R-MV-25-8 - Ø25.0 mm × 25.0 mm V magnet with M8 thread

This V magnet is ideal for holding ferrous cylindrical workpieces and tubing. It is recommended for use on CMMs and the Equator™ gauging system.