Filter by

Results found for “Manual setting and NC programming is needless torture for machine operators…”

Aston Martin x J.Laverack .1R bike at J Laverack HQ

Renishaw has collaborated with J.

Renishaw considers a proposal to co-locate its additive manufacturing teams

Global engineering technologies company, Renishaw, is evaluating a potential reorganisation of its additive manufacturing (AM) business by co-locating its AM engineering, marketing and commercial...

Process control demo wall

This is the16x9 version of the 3 screen process control display. If you require another screen size please contact Group Marketing Services.

Renishaw's education outreach team makes Cheltenham Science Festival debut

In June 2019, the education outreach team from Gloucestershire-based global engineering technologies company, Renishaw, attended the Cheltenham Science Festival for the first time.

Renishaw apprentices win People’s Prize at Engineers without Borders event

Five degree apprentices from global engineering technologies company, Renishaw, were recently awarded the People’s Prize for their entry in the national Engineers without Borders competition.

Anterior and posterior copings

Anterior and posterior copings, showing different thicknesses and maximum loads.

Renishaw apprenticeship schemes

A Renishaw apprenticeship comes with over 30 years of our experience and commitment in training and developing people as part of our award winning scheme.

A-9585-0028 - Datum clamp for adhesive mounted RTL linear encoder tape scales

A-9585-0028 Datum clamp for adhesive mounted RTL linear encoder tape scales The datum clamp creates a thermal datum on the encoder scale using Loctite® 435.

Renishaw reflects on 50 years of British innovation

In 2019, engineering companies throughout the UK are celebrating the 50th anniversary of the prestigious MacRobert Award, the country’s longest running prize for engineering innovation.

Formnext 2018 - Productivity without compromise

Global engineering company Renishaw returns to Formnext in 2018 to showcase that it is possible to significantly increase additive manufacturing (AM) productivity without compromising on quality.

Haas manufacturing case study image - ballbar

The QC10 ballbar test is controlled with software on a PC, the data gathered will then be analysed with Ballbar diagnostic software off-line

504 Vacuum casting machine ECD2016-78

Declaration of conformity with relevant European Union legislation and technical standards.

501 Vacuum casting machine ECD2016-77

Declaration of conformity with relevant European Union legislation and technical standards.

A-5555-0196 - M5 high strength steel spherical disc, DK 15 mm, for ZEISS applications

A-5555-0196 M5 high strength steel spherical disc, DK 15 mm, for ZEISS applications M5 spherical disc.

A-5555-0200 - M5 high strength steel spherical disc, DK 50 mm, for ZEISS applications

A-5555-0200 M5 high strength steel spherical disc, DK 50 mm, for ZEISS applications M5 spherical disc.

A-5555-0205 - M8 high strength steel spherical disc, DK 30 mm, for ZEISS applications

A-5555-0205 M8 high strength steel spherical disc, DK 30 mm, for ZEISS applications M8 spherical disc.

A-5555-0208 - M8 high strength steel spherical disc, DK 60 mm, for ZEISS applications

A-5555-0208 M8 high strength steel spherical disc, DK 60 mm, for ZEISS applications M8 spherical disc.

A-5555-0197 - M5 high strength steel spherical disc, DK 20 mm, for ZEISS applications

A-5555-0197 M5 high strength steel spherical disc, DK 20 mm, for ZEISS applications M5 spherical disc.

A-5555-0198 - M5 high strength steel spherical disc, DK 30 mm, for ZEISS applications

A-5555-0198 M5 high strength steel spherical disc, DK 30 mm, for ZEISS applications M5 spherical disc.

A-5555-0199 - M5 high strength steel spherical disc, DK 40 mm, for ZEISS applications

A-5555-0199 M5 high strength steel spherical disc, DK 40 mm, for ZEISS applications M5 spherical disc.

A-5555-0201 - M5 high strength steel spherical disc, DK 60 mm, for ZEISS applications

A-5555-0201 M5 high strength steel spherical disc, DK 60 mm, for ZEISS applications M5 spherical disc.

A-5555-0206 - M8 high strength steel spherical disc, DK 40 mm, for ZEISS applications

A-5555-0206 M8 high strength steel spherical disc, DK 40 mm, for ZEISS applications M8 spherical disc.

A-5555-0207 - M8 high strength steel spherical disc, DK 50 mm, for ZEISS applications

A-5555-0207 M8 high strength steel spherical disc, DK 50 mm, for ZEISS applications M8 spherical disc.

P-CN24-0039 - Con circ plug 2 wire (trigger connector)

P-CN24-0039 Con circ plug 2 wire (trigger connector) A connector to allow for the trigger input feature within an RSU10 to be utilised.

R-CH-138 - 53.3 mm × 141.3 mm Hold down clamp

R-CH-138 53.3 mm × 141.3 mm Hold down clamp Used to secure workpieces in place. For more clamping force than a standard tension clamp.

A-4113-0306 - RMI-OMI-2 conduit kit (1 m)

A-4113-0306 RMI-OMI-2 conduit kit (1 m) Conduit set for RMI/OMI-2 interfaces with 1 m (3.28 ft) of metal conduit.

Part programs for ISO 10791-6

Specific part programs need to be created, to perform tests conforming to ISO 10791-6.

MI 8-4 interface unit

The MI 8-4 interface processes the probe signal from a hard wired probe and converts it into the correct format to connect into a controller's probe input.

Ballbar and interface

QC10 Ballbar and interface

Exhibitions and conferences

Renishaw events and exhibitions

Abutment and Link

Link and Abutment image

OSP60 scanning probe - Adaptive machining

OSP60 scanning probe with Sprint Technology scanning a toolpath for adaptive machining.

OSP60 scanning probe - Adaptive machining

OSP60 scanning probe with Sprint Technology scanning a toolpath for adaptive machining.

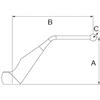

Technical drawing for M4 stylus crank

A stylus crank is used to offset the stylus.

Application image for M4 stylus crank

A stylus crank is used to offset the stylus.

Primo™ radio part setter

First "pay-as-you-go" probing system for entry-level users

Primo™ radio part setter

First "pay-as-you-go" probing system for entry-level users

A-5555-0104 - M5 stainless steel, 90° stylus holder, L 40 mm, for ZEISS applications

A-5555-0104 M5 stainless steel, 90° stylus holder, L 40 mm, for ZEISS applications M5 90° stylus holder.

Annual report: 2017

Annual report and accounts 2017

Annual report: 2016

Annual report and accounts 2016

MCG machine checking gauge

calibration,cmm.mcg

MCG machine checking gauge

calibration,cmm,mcg

A-5225-0565 - Dual axis RLU connector kit

A-5225-0565 Dual axis RLU connector kit A connector kit for use with the dual axis RLU which contains the connectors as listed.