Filter by

Results found for SiGNUM™ software

News release - Spotlight on productive additive manufacturing at MACH 2018

At MACH 2018, held at the NEC in Birmingham, UK, from April 9th-13th, global engineering company, Renishaw, showcased the benefits of its additive manufacturing products range to manufacturers.

Additive manufacturing for serial production of orthopaedic implants

Croom Precision Medical has chosen Renishaw as their additive manufacturing (AM) and metrology partner, utilising Renishaw technology throughout the production and validation of their ISO13485...

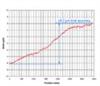

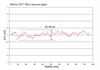

Data stitch brings improved accuracy and testing to international standards for long axes

The latest release of CARTO software suite, version 4.

Smart 5-axis measurement with XM-60 multi-axis calibrator

Renishaw’s latest release of its CARTO software suite, version 4.

Senior UK Minister visits Renishaw during India-UK TECH Summit

Renishaw, the global engineering technologies company, hosted a visit to its Pune, India facility on 9th November 2016 by The Rt Hon Liam Fox MP, British Secretary of State for International Trade.

Liam Fox with Renishaw metal additive manufacturing machine

Renishaw, the global engineering technologies company, hosted a visit to its Pune, India facility on 9th November 2016 by The Rt Hon Liam Fox MP, British Secretary of State for International Trade.

Secretary of State Liam Fox (right) plants commemorative tree with Renishaw's Rhydian Pountney

Renishaw, the global engineering technologies company, hosted a visit to its Pune, India facility on 9th November 2016 by The Rt Hon Liam Fox MP, British Secretary of State for International Trade.

PAL Robotics integrates magnetic encoder technology into robots to achieve balance

This case study focuses on REEM-C, PAL Robotics' full-size biped humanoid robotics research platform.

TONiC™ T20x1 RESM with Ri compact interface

Installation guide for the TONiC T20x1 RESM incremental encoder system with the Ri compact interface.

Equator™ gauging system ensures pneumatic component quality

Increasing pressure on high-volume production, whilst maintaining strict part tolerances, demanded a move away from traditional manual inspection and measurement techniques.

Equator™ gauge case brief page banner image

An image of a part being inspected on an Equator gauge. This image is used as the banner on the Equator case briefs webpage.

Renishaw OSP60 SPRINT™ technology - measuring rough surfaces

Measuring rough surfaces with a touch-trigger probing system is time consuming, as it requires a lot of data points to be taken in order to get a sufficient amount of data to define the surface.

Primo™ on a machine at SuMax Enterprises

SuMax Enterprises was established in 1979 to facilitate additional capacity to manufacture different products for its parent company, Vijay Engineering, a manufacturer of tooling systems and...

QuickLoad™ rail and plates - Why choose Renishaw?

A flyer explaining the features of the QuickLoad rail and plates system

SOLPOWER rotary tables turn on RESOLUTE™ encoders

SOLPOWER is a Taiwanese manufacturer of machine tool components such as Direct-Drive (DD) rotary tables, integrated spindle motors and linear motors.

Creation and calibration of your probe: Productivity+™

This module demonstrates how to create a new probe in the Probe Database and how to create a calibration program which must be run on a machine prior to any inspection cycles.

Renishaw launches the QUANTiC™ rotary encoder system

QUANTiC rotary encoder press release

Including tool setting in your program: Productivity+™

This module demonstrates how to add a tool setting function or broken tool detection into a program.

Equator™ IPC - Offsets applied in Process Monitor

IPC offset updates being applied to a manufacturing process using Equator gauging data displayed in the Process Monitor view – the green icons show the point at which an update is applied

M6 CMM and Equator™ clamping kit A

This essential M6 clamping component set can be used to hold brass, titanium, aluminium, plastic, ferrous and non-ferrous parts.

RESOLUTE™ ETR (Extended Temperature Range) absolute encoder

RESOLUTE ETR is a revolutionary new true absolute, fine pitch optical angle encoder system, with excellent dirt immunity, wide set-up tolerances, fine resolution and now with guaranteed operation...

Equator™ gauge display at EMO Hannover 2019

Equator gauge display on the main stand at EMO 2019.

Equator™ - 27% reduction in part production cost

High-Tech Engineering, a precision engineering company based in Dunstable, Bedfordshire, UK, has always focused on the quality of the parts it produces.