Filter by

Results found for Software

Process Monitor remastering software for Equator™

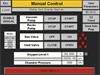

Process monitor window

Manual CMM upgrade kit specification

A Renishaw manual CMM retrofit transforms your machine into a fast, easy to use measurement facility.

MODUS Planning suite_ Curve icon

MODUS Planning suite applications offer a a set of automated shortcuts to frequent challenges in part programming, maximising the efficiency of the REVO CMM system with easy to use specialised...

MODUS Planning suite_ Patch icon

MODUS Planning suite applications offer a a set of automated shortcuts to frequent challenges in part programming, maximising the efficiency of the REVO CMM system with easy to use specialised...

Renishaw recruits for new graduate intake

Gloucestershire-based engineering company Renishaw is recruiting 70 graduates for its 2020 intake.

Renishaw at Control 2009

Renishaw will be announcing a series of major new initiatives at Control 2009 (stand 3304, hall 3), including its first CMM retrofit service, its first metrology software, a new surface finish probe...

MCU5

MCU5 Retrofits Learn about retrofitting options for your CMM.

Establishing a docking position for SH25 stylus holders

Establishing a docking position for SH25 stylus holders This section describes how to establish the docking position for the SH25 stylus holder.

InfiniAM Central

InfiniAM Central Remote process monitoring for additive manufacturing systems Key benefits Current status From the Current Status page, users have visibility of all the resources within their...

Innovation Matters

Innovation Matters Sharing our expertise with our global partners As manufacturers ourselves, we understand the challenges that our global customers face every day.

LTS (length tool setter)

The LTS is a single-axis length tool setter which, when used in conjunction with LTS application software, provides users with the ability to set tool length, check for tool wear and tool breakage...

Discover the RenAM 500 series (Americas)

The RenAM 500 series is Renishaw's metal laser powder bed fusion (LPBF) system.

Calibration FAQs

Calibration FAQs I may need to use my XR20 rotary axis calibrator in other countries.

Ronchini Milling Technologies chooses Renishaw metrology products to enhance cutting-edge milling machines

Ronchini Milling (RM) Technologies specialises in CNC milling machines for non-ferrous metals, composites, and foam materials.

Create and align co-ordinate systems: Active Editor Pro

Dialogs assist in the creation and alignment of co-ordinate systems

Feature selection: Active Editor Pro

Select a feature type from the menu bar and use the mouse pointer to select matching features on the solid model. Users without solid models can program using the Basic Statements toolbar

Renishaw retrofit

Transform your old CMM with a new lease of life, speed and capability

FixtureBuilder 8.2

FixtureBuilder download manager is an EXE file that can be easily downloaded from a Web page and run by the end user.

Add intelligent, in-process decision making: Active Editor Pro

Use the Condition Builder to program logic statements allowing intelligent in-process decision making

Create and edit probe configurations: Active Editor Pro

Define the configuration of your probe by selecting standard probe modules and styli, or define individual parameters for a custom probe specification

Productivity+ Active Editor Pro

Productivity+ Active Editor Pro. Design probing cycles on the PC from the CAD model using solid model feature selection

Prove out the program: Active Editor Pro

Program visualisation helps to identify potential probe:component or probe:machine collisions

Post process the program: Active Editor Pro

Use the Post Process dialog to convert the Productivity+ program into code that the CNC machine tool can read and execute

Tool setting: Active Editor Pro

Use menu options to add tool setting routines prior to machining operations and to check tool geometry after component measurement cycles

2017 Equator™ homepage website_banner

2017 Equator homepage website banner image with IPC (Intelligent Process Control)

Report on features and updates: Active Editor Pro

Create reports on inspected features and machine and tool updates performed during the measurement cycle