Filter by

Results found for “Manual setting and NC programming is needless torture for machine operators…”

A-5555-1241 - M3 aluminium adaptor plate with star adaptor, VAST XXT TL1, L 55mm, for ZEISS applications

A-5555-1241 M3 aluminium adaptor plate with star adaptor, VAST XXT TL1, L 55mm, for ZEISS applications M3 adaptor plate VAST XXT TL1 with star adaptor.

FR - Sécurité

FR - Sécurité Sortie laser Sortie maximale : < 5 mW Durée de l'impulsion : onde continue Longueur d'ondes : 670 nm Divergence faisceau : 2 mrad Le corps du SFP1 renferme des sources laser...

Greenwich University RPC opening with Johnathon Shaw MP

22 October 2008, Official opening of the Renishaw Centre for Manufacturing Productivity at the Univeristy of Greenwich

Sir David McMurtry and John Deer

Chairman and Chief Executive and Deputy Chairman

A-6852-6600 - RCS datum ball kit

Calibrate your RCS probe with the RCS datum ball kit.

REVO-2 and SFP2 measuring Sandvik blisk

Sandvik blisk inspection with REVO-2 and SFP2 on an AGILITY CMM (close up) - dark.

EasyProbe software for machining centres

Data sheet - EasyProbe software for machining centres

Vision fixtures for Nikon systems

Vision fixtures for Nikon system data sheet

Vision fixtures for OGP systems

Vision fixtures for OGP systems data sheet.

Vision fixtures for Mitutoyo systems

Vision fixtures for Mitutoyo systems - data sheet

Vision fixtures for Starrett systems

Vision fixtures for Starrett systems data sheet

Plastic carry cases for sets

Image of plastic carry cases for sets

Vision fixtures for ZEISS systems

Vision fixtures for ZEISS systems data sheet

Welcome to Renishaw AM Solutions Center - Illinois, USA

Welcome to Renishaw’s AM Solutions Center in West Dundee, Illinois.

Renishaw precision styli

Promotional video advertising the range and services that Renishaw precision styli offer. Dual language English and Italian

Railway engine turbocharger housing: reducing cycle times through in-process control

Case brief highlighting the challenges faced by an Indian end user (Universal Manufacturing Company) when producing large turbocharger housing and how Renishaw systems helped overcome them.

Ti6Al4V ELI-0406 powder for additive manufacturing

Data sheet for metal powders for additive manufacturing supplied by Renishaw.

SS 316L-0407 powder for additive manufacturing

Data sheet for metal powders for additive manufacturing supplied by Renishaw.

5-axis measurement systems

Unlike conventional CMM measurement methods, Renishaw's 5-axis technology uses the synchronised motion of the CMM and the head axes to minimise the machine's dynamic errors at ultra‑high measuring speeds.

A-5439-0049 - OMI-2T optical interface/receiver (8 m)

A-5439-0049 OMI-2T optical interface/receiver (8 m) OMI-2T assembly including an 8 m exit cable, tool kit and magnetic label.

A-5439-0050 - OMI-2T optical interface/receiver (15 m)

A-5439-0050 OMI-2T optical interface/receiver (15 m) OMI-2T assembly including a 15 m exit cable, tool kit and magnetic label.

REVO-2 and SFP2 measuring Sandvik blisk

Sandvik blisk inspection with REVO-2, SFP2 and MCU joystick on an AGILITY CMM - dark.

Custom solutions

Short movie for the web

Low power RLD detector heads

The RLE system comprises an RLU laser unit and one or two RLD detector heads.

RTLA30 absolute linear scale

RTLA absolute linear encoder tape scale from Renishaw combines ±5 μm/m accuracy with the ruggedness of stainless steel.

A-5492-0051 - OMM-2 with 25 m (82 ft) cable

A-5492-0051 OMM-2 with 25 m (82 ft) cable OMM-2 receiver with 25 m (82 ft) cable, tools and product support card.

A-5687-0050 - RMI-Q interface (15 m) (level) side exit

A-5687-0050 RMI-Q interface (15 m) (level) side exit This RMI-Q interface includes a 15 m side exit cable and tool kit.

A-5687-1050 - RMI-Q interface (15 m) (pulsed) side exit

A-5687-1050 RMI-Q interface (15 m) (pulsed) side exit This RMI-Q interface includes a 15 m side exit cable and tool kit.

A-5492-0049 - OMM-2 with 8 m (26 ft) cable

A-5492-0049 OMM-2 with 8 m (26 ft) cable OMM-2 receiver with 8 m (26 ft) cable, tools and product support card.

A-5492-0050 - OMM-2 with 15 m (49 ft) cable

A-5492-0050 OMM-2 with 15 m (49 ft) cable OMM-2 receiver with 15 m (49 ft) cable, tools and product support card.

A-5687-0049 - RMI-Q interface (8 m) (level) side exit

A-5687-0049 RMI-Q interface (8 m) (level) side exit This RMI-Q interface includes an 8 m side exit cable and tool kit.

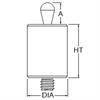

A-6560-2654 stylus for BLUM probes

Web shop drawing for A-6560-2654 stylus for BLUM spindle probes

A-6560-2659 stylus for BLUM probes

Web shop drawing for A-6560-2659 stylus for BLUM spindle probes

A-6560-2655 stylus for BLUM probes

Web shop drawing for A-6560-2655 stylus for BLUM spindle probes

A-6560-2657 stylus for BLUM probes

Web shop drawing for A-6560-2657 stylus for BLUM spindle probes

A-6560-2653 stylus for BLUM probes

Web shop drawing for A-6560-2653 stylus for BLUM spindle probes

A-6560-2656 stylus for BLUM probes

Web shop drawing for A-6560-2656 stylus for BLUM spindle probes

A-6560-2658 stylus for BLUM probes

Web shop drawing for A-6560-2658 stylus for BLUM spindle probes

Technical drawing for spring pusher standoff clamp

Technical drawing for the spring pusher standoff clamp. For the Fixturing webshop.