Filter by

Results found for “Manual setting and NC programming is needless torture for machine operators…”

A-5555-0207 - M8 high strength steel spherical disc, DK 50 mm, for ZEISS applications

A-5555-0207 M8 high strength steel spherical disc, DK 50 mm, for ZEISS applications M8 spherical disc.

Wear comparison testing between Renishaw OPTiMUM diamond styli and the standard ruby equivalent

OPTiMUM diamond styli white paper preview image - Wear comparison testing between Renishaw OPTiMUM diamond styli and the standard ruby equivalent

Renishaw's education outreach team makes Cheltenham Science Festival debut

In June 2019, the education outreach team from Gloucestershire-based global engineering technologies company, Renishaw, attended the Cheltenham Science Festival for the first time.

Renishaw apprentices win People’s Prize at Engineers without Borders event

Five degree apprentices from global engineering technologies company, Renishaw, were recently awarded the People’s Prize for their entry in the national Engineers without Borders competition.

Anterior and posterior copings

Anterior and posterior copings, showing different thicknesses and maximum loads.

Process control demo wall

This is the16x9 version of the 3 screen process control display. If you require another screen size please contact Group Marketing Services.

501 Vacuum casting machine ECD2016-77

Declaration of conformity with relevant European Union legislation and technical standards.

504 Vacuum casting machine ECD2016-78

Declaration of conformity with relevant European Union legislation and technical standards.

P-CN24-0039 - Con circ plug 2 wire (trigger connector)

P-CN24-0039 Con circ plug 2 wire (trigger connector) A connector to allow for the trigger input feature within an RSU10 to be utilised.

R-CH-138 - 53.3 mm × 141.3 mm Hold down clamp

R-CH-138 53.3 mm × 141.3 mm Hold down clamp Used to secure workpieces in place. For more clamping force than a standard tension clamp.

A-4113-0306 - RMI-OMI-2 conduit kit (1 m)

A-4113-0306 RMI-OMI-2 conduit kit (1 m) Conduit set for RMI/OMI-2 interfaces with 1 m (3.28 ft) of metal conduit.

FCR25 TC temperature controlled flexible change rack

FCR25 TC temperature controlled flexible change rack FCR25 TC is similar in function to the standard FCR25, the main difference being that temperature compensation is provided to optimise scanning...

Enhancing the additive manufacturing process chain

The design freedom provided by additive manufacturing (AM) or ‘3D printing’ technology is an important enabler in cutting-edge product innovation.

Distribution box

The sensor Distribution box allows up to four sensors to be connected to a single RCU10 sensor port.

Exchanging metal 3D printing solutions with HiETA

Technology from Renishaw is helping HiETA to move metal additive manufacturing (AM) from prototype manufacture into commercial production of its specialist range of heat exchangers.

Aston Martin x J.Laverack .1R bike at J Laverack HQ

Renishaw has collaborated with J.

Dassault Systemes case study

The design freedom provided by additive manufacturing (AM) or ‘3D printing’ technology is an important enabler in cutting-edge product innovation.

Renishaw considers a proposal to co-locate its additive manufacturing teams

Global engineering technologies company, Renishaw, is evaluating a potential reorganisation of its additive manufacturing (AM) business by co-locating its AM engineering, marketing and commercial...

A-5555-0104 - M5 stainless steel, 90° stylus holder, L 40 mm, for ZEISS applications

A-5555-0104 M5 stainless steel, 90° stylus holder, L 40 mm, for ZEISS applications M5 90° stylus holder.

UCC DMT safety

UCC DMT safety If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

PT - Segurança

PT - Segurança Tome cuidado com movimentos inesperados.

Part programs for ISO 10791-6

Specific part programs need to be created, to perform tests conforming to ISO 10791-6.

Ballbar and interface

QC10 Ballbar and interface

Exhibitions and conferences

Renishaw events and exhibitions

Abutment and Link

Link and Abutment image

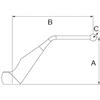

Technical drawing for M4 stylus crank

A stylus crank is used to offset the stylus.

Application image for M4 stylus crank

A stylus crank is used to offset the stylus.

Renishaw reflects on 50 years of British innovation

In 2019, engineering companies throughout the UK are celebrating the 50th anniversary of the prestigious MacRobert Award, the country’s longest running prize for engineering innovation.

A-4038-0001 - OMP60 probe (optical/optical - legacy)

A-4038-0001 OMP60 probe (optical/optical - legacy) OMP60 probe kit including batteries and tool kit.

A-4038-0002 - OMP60 probe (optical/time - legacy)

OMP60 probe kit including batteries and tool kit.

A-4038-2001 - OMP60 probe (optical/optical - modulated)

A-4038-2001 OMP60 probe (optical/optical - modulated) OMP60 probe kit including batteries and tool kit.

A-4038-2002 - OMP60 probe (optical/time - modulated)

A-4038-2002 OMP60 probe (optical/time - modulated) OMP60 probe kit including batteries and tool kit.

A-5225-0565 - Dual axis RLU connector kit

A-5225-0565 Dual axis RLU connector kit A connector kit for use with the dual axis RLU which contains the connectors as listed.

Formnext 2018 - Productivity without compromise

Global engineering company Renishaw returns to Formnext in 2018 to showcase that it is possible to significantly increase additive manufacturing (AM) productivity without compromising on quality.

Haas manufacturing case study image - ballbar

The QC10 ballbar test is controlled with software on a PC, the data gathered will then be analysed with Ballbar diagnostic software off-line

Videos tile for website

Videos tile for website

RCPTC image for webpage

RCPTC image for webpage

Design support for pipe

Design support for pipe

Connecting SP80 / SP80H using UCC PI 80

Connecting SP80 / SP80H using UCC PI 80 The UCC PI 80 has different configuration layouts to provide an interface to CMM systems with three, four or five machine axes, whether brushed or brushless...

Annual report: 2017

Annual report and accounts 2017

Annual report: 2016

Annual report and accounts 2016

Robot Bike Co. - The final stage in the production of the titanium parts is inspection using Renishaw probes

The final stage in the production of the titanium parts is inspection using Renishaw probes.

XR20-W rotary axis calibrator

XR20-W allows the measurement of rotary axis positional accuracy to within ±1 arc second. Totally wireless operation and modular mounting systems ensure suitability for a wide range of machines.

Automated workpiece set-up boosts forestry equipment manufacture

To meet rising demand for its market-leading range of forestry equipment, Tigercat Industries Inc.

Virsa Raman analyser with probe

The transportable Virsa analyser consists of a fibre-optic probe and a rack-mountable spectrometer box. For transportable Raman imaging, the Virsa probe can be mounted on motorised XYZ stages.

Renishaw personnel & Air Chief Marshall at RAF Wittering

Stephen Crownshaw and Antonio Marques from Renishaw’s Additive Manufacturing Division with Air Chief Marshall Sir Mike Wigston CBE ADC at the opening of the Hilda B Hewlett Centre for Innovation.