Filter by

Results found for renishaw

Group profile: 2001 - CMM & machine tools

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

Industrial 3D printing yields success on the Formula Student circuits

The GreenTeam and Renishaw - a premium sponsor - have collaborated to develop and manufacture optimised wheel carriers for a Formula Student racing car, reducing the overall weight of the car by 1.

Group profile: 2001 - Spectroscopy & sales support

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

Group profile: 2004

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

APCA-45H addendum - APCA-45H tool setting probe

This addendum serves to support the introduction of the APCA-45H high force kinematic tool setting probe and should be read in conjunction with the APCA-45 tool setting probe installation and user’s...

Group profile: 2001 - Styli, custom products, laser scales & calibration

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

Group profile: 2001 - Wotton travel & summary

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

ADTpro-100 Advanced Diagnostic Tool

The ADTpro-100 Advanced Diagnostic Tool features a colour touch screen, displaying detailed encoder information without the need to connect to an external computer.

Free US technical seminars to focus on motion system accuracy

To update motion system designers with the latest technologies available for position feedback, performance analysis and calibration, world leading metrology company Renishaw will present free...

Mounting kit (steel)

The steel optics mounting kit is for use with all Renishaw measurement optics.

Group profile: 2001 - Research & development & manufacturing

Renishaw's Group profile: is produced as an accompaniment to the company's Annual report, but it is also available as a separate publication.

SPAlite (H-1000-5107) - legacy

The SPAlite is a servo power amplifier designed specifically for use with the Renishaw UCC2 and UCClite controllers.

Announcement regarding settlement of patent litigation 09-02-09

Renishaw plc, Tesa SA and Hexagon Metrology, Inc.

Getting to the heart of technology

Dave Collingwood, Principal Engineer at global engineering technologies company Renishaw, explains the benefits of Technology Teardown workshops, where students, aided by engineers, disassemble...

Sewtec Automation - Machining capacity up 850% with just 80% more machines

Sewtec Automation, a world leading supplier of production and packaging systems for the fast moving consumer goods sector, has dramatically increased machining output by adding 5 new HAAS machine...

Sewtec Automation - Machining capacity up 850% with just 80% more machines

Sewtec Automation, a world leading supplier of production and packaging systems for the fast moving consumer goods sector, has dramatically increased machining output by adding 5 new HAAS machine...

Compliance of QC20 ballbar with radio device regulations

The Renishaw QC20 ballbar uses Bluetooth® wireless technology.

IS1-2

This guide describes how the IS1-2 (interface selector) functions when used with multiple Renishaw probing systems.

Sample positioning for Raman microscopy

Renishaw’s encoded microscope stages move the sample with the high precision required for accurate Raman analysis.

Motorised head and autochange rack controllers

A range of control systems to interface between Renishaw's motorised heads and autochange racks and your CMM.

Machine tool probing increases productivity for Australian machine shop

When Australia-based machine shop, Hammond Engineering, found that manually setting workpiece positions was time consuming and difficult to repeat, it looked to the potential of on-machine probing.

Renishaw launches super-productive RenAM 500 Ultra at Formnext 2023

Press release for release of new RenAM 500 Ultra model of metal AM machines

Custom Renishaw Raman probe interface deployed on the SNBL beamline

Part of the custom Raman probe deployed on the SNBL Beamline, ESRF, Grenoble, France.

Renishaw and Hartford combine to deliver intelligent, ‘smart factory’ solutions

Established in 1965, Hartford is Taiwan’s biggest exporter of CNC machining centres as well as being the country’s largest machining centre manufacturer.

Renishaw supports new US HTEC centre with performance testing tool

Haas, one of the world’s leading machine tool manufacturers, has boosted its Haas Technical Education Centre (HTEC) programme in the USA, with the opening of a dedicated HTEC teacher training centre...

Renishaw launches functional safety variant of FORTiS™ enclosed encoder

Press release announcing the launch of the FORTiS FS encoder.

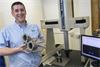

Renishaw AM systems were used to realise the physical part

An image of a RenAM 500M with a worker.

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Renishaw and Hartford combine to deliver intelligent, ‘smart factory’ solutions

Established in 1965, Hartford is Taiwan’s biggest exporter of CNC machining centres as well as being the country’s largest machining centre manufacturer.

Renishaw Greenpower car on the track (image credit: John Robbens)

Greenpower races require teams to design, build and race fully functioning electric vehicles.

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Certificate: Renishaw Ireland CERT-155 FOBY:9001 2015 INAB (1)

Design, development, manufacture and servicing of metrology systems; Certification body - NSAI; Standard - ISO 9001