Filter by

Results found for renishaw

Renishaw launches functional safety variant of FORTiS™ enclosed encoder

Press release announcing the launch of the FORTiS FS encoder.

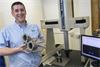

Renishaw AM systems were used to realise the physical part

An image of a RenAM 500M with a worker.

Renishaw and Hartford combine to deliver intelligent, ‘smart factory’ solutions

Established in 1965, Hartford is Taiwan’s biggest exporter of CNC machining centres as well as being the country’s largest machining centre manufacturer.

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Certificate: Renishaw Ireland CERT-155 FOBY:9001 2015 INAB (1)

Design, development, manufacture and servicing of metrology systems; Certification body - NSAI; Standard - ISO 9001

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Renishaw Greenpower car on the track (image credit: John Robbens)

Greenpower races require teams to design, build and race fully functioning electric vehicles.

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Renishaw plc at New Mills, Charfield and Old Town, Gloucestershire

Directions to our New Mills, Charfield and Old Town offices in the UK.

‘Seamless’ probe head upgrade advances part inspection - all files

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

David Clow, Joe McMurtry and Oli Laverack with the Aston Martin .1R bike

This image is showing the luxury bike being presented in front of Joe McMurtry, David Clow and Oli Laverack.

Motorised probe head

This straight cable has an in-line LEMO plug at end 'A' and an in-line Tuchel socket at end 'B'. It electrically connects Renishaw PH10T, PH10M or PH10MQ motorised probe heads to the CMM quill.

New stylus catalogue from world leader in metrology

Renishaw has introduced version 12 of its popular stylus catalogue that will be of interest to all users of touch probes, whether installed on co-ordinate measuring machines (CMMs), CNC machine tools...

Achieving reliable, accurate tool setting for Standard Tool & Mold

When Standard Tool & Mold Inc needed support with its on-machine tool measurement technology, it turned to global engineering technologies company Renishaw, who supplied the new NC4+ Blue tool sett...

(IN503) Case study: Rousant Sherwood - ‘Seamless’ probe head upgrade advances part inspection

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

Manifold part for the BR-XX

Renishaw is contributing its additive manufacturing (AM) expertise to help create a manifold part for the BR-XX, which will be used to compete at FS-UK in Silverstone and FS-ATA in Italy in July.

Rousant Sherwood - ‘Seamless’ probe head upgrade advances part inspection

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

Rousant Sherwood - ‘Seamless’ probe head upgrade advances part inspection

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

Motorised probe head cable

This straight cable has an in-line LEMO plug at end 'A' and a 90° Tuchel type socket at end 'B'. It electrically connects Renishaw PH10T, PH10M or PH10MQ motorised probe heads to the CMM quill.

SPRINT™ DPU-1 Data Processing Unit

Renishaw, a world-leading engineering technologies company, will demonstrate a new member of its award-winning SPRINT™ product family for on-machine scanning at EMO Hannover 2017, Hannover (18th–23rd...

Rousant sherwood - complex parts

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

Rousant sherwood - complex parts

When Renishaw announced the PH10T upgrade offer for the obsolete PH9 motorised probe head systems, Rousant Sherwood of Henley-on-Thames, a specialist manufacturer of multi-axis machined components,...

Non-contact tool setter – How to perform missing insert and edge checking using the NC4

In this how-to series, Dan and Iain show how to check the edges of a tool, which they demonstrate using an NC4+ Blue.

SFP2 surface finish probe for REVO at MACH 2018

Renishaw, a world leading manufacturer of co-ordinate measuring machine (CMM) equipment, will be showing its new, improved surface finish measurement probe (SFP2) for use with its REVO 5-axis...

Imperial and metric high quality metrology fixtures

Global engineering technologies company Renishaw is introducing a ¼ 20 imperial thread size to its existing metrology fixtures product range.

Boxtrees Precision - Scheduling system for overnight work

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

RNS privacy notice

This privacy notice is published by RNS who are acting as a controller of your data so when we mention RNS, “we”, “us” or “our” in this privacy notice, we are referring to Renishaw Neuro Solutions Ltd.

Boxtrees Precision - Boxford machine during test

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Manual probe head cable

These coiled cables have an in-line 5-pin DIN plug at end 'A' and a 90° moulded plastic 5-pin DIN plug at end 'B'. They electrically connect Renishaw manual probe heads to the CMM quill.

Boxtrees Precision - “Throw the machining rule book away and get creative"

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Boxtrees Precision - measured data recorded for spc

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Manual probe head cable

This straight cable has an in-line 5-pin DIN plug at end 'A' and a 90° moulded plastic 5-pin DIN plug at end 'B'. It electrically connects Renishaw manual probe heads to the CMM quill.

Boxtrees Precision

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Hewland case study image

Fast tool setting is made possible through the use of this Renishaw NC1 laser system.

Latest position feedback encoders to be shown at Korean automation show

Renishaw is highlighting its new range of encoder and calibration solutions at Korea€s International Automation, Instrumentation and Control System Exhibition (AIMEX), being held at the COEX exhibi...

Boxtrees Precision - billet and finished part

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

HS10 to HS20 upgrade

With many HS10s sold in the 1990s coming to the end of their serviceable lives, Renishaw has shown its commitment to this specialised sector of the machine tool market by introducing its HS20 long...

Boxtrees Precision - OMP400 touch probe inspecting finished billet

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Boxtrees Precision - Steve Randerson with bar component

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

Boxtrees Precision

Boxtrees Precision Engineering use Renishaw probe systems on a Mazak Integrex in a clever fully-integrated ‘intelligent’ system that has achieved reduced unit costs, zero manual set-up times, unman...

BiSS® C-mode (unidirectional) for RESOLUTE™ and FORTiS™ encoders

Renishaw encoders use BiSS C-mode (unidirectional) serial protocol and output 32-bit or 26-bit position information (single-turn for rotary).

Mekall – HAAS machines in shop

Defence & telecommunications supplier ‘would not operate a machine without probes’.