Filter by

Results found for renishaw

OMP400

The OMP400 from Renishaw is an innovative, ultracompact strain gauge probe for small machining centres, offering reduced set-up times, reduced scrap, reduced fixture costs, improved process control...

Manual probe head cable

These coiled cables have a 90° moulded 5-pin DIN plug at end 'A' and an in-line LEMO plug at end 'B'. They electrically connect Renishaw manual probe heads to the CMM quill.

Senior politician visit

On Thursday 14th June, world leading metrology company Renishaw plc hosted a visit by Alan Duncan MP, the Shadow Secretary of State for Trade, Industry & Energy, at its manufacturing facility at St...

Manual probe head cable

This straight cable has an in-line 5-pin DIN socket at end 'A' and an in-line LEMO plug at end 'B'. It electrically connects Renishaw manual probe heads to the CMM quill.

Defiant innovation at Industrie 2016

Renishaw, a world leader in precision engineering technologies, will be exhibiting its extensive range of metrology and additive manufacturing equipment at Industrie 2016 which takes place in Paris,...

Volumetric compensation with XM-60 multi-axis calibrator

Renishaw Compensate is a new addition to the CARTO software suite.

PH20 in action at Measurement Solutions Ltd (image courtesy of MSL)

Renishaw, one of the world’s leading precision engineering and scientific technology companies, has announced the appointment of Measurement Solutions Ltd (MSL) - the Peterborough, UK-based scanning...

New software extends QC20-W ballbar capability for time based data capture

Renishaw is introducing Ballbar Trace at EMO 2015; a new time based data capture software package for the company’s QC20-W ballbar which is used to verify the positioning performance of CNC machine tools.

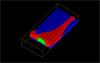

Multiple component 3D Raman volume image of a glioma cell.

Multiple component 3D Raman volume image of a glioma cell.

MI 8-4 interface unit

CNC machine tools using a Renishaw probe system for tool setting or workpiece set-up and inspection require an interface unit, to convert probe signals into an acceptable form for the CNC machine...

Non-contact tool setter – How to perform missing insert and edge checking using the NC4

In this how-to series, Dan and Iain show how to check the edges of a tool, which they demonstrate using an NC4+ Blue.

Machine cable

This straight cable has an in-line LEMO plug at end 'A' and an in-line 5-pin DIN socket at end 'B' and. It electrically connects Renishaw manual probe heads to the CMM quill.

MP250 high accuracy probe for grinding machines

Renishaw launches the world’s first strain gauge based inspection probe for grinding machines.

RLS magnetic encoders enable Marsi Bionics to build ‘life-changing’ exoskeletons

RLS, a Renishaw associate company, has been chosen by Marsi Bionics to supply the latest in magnetic encoder technology for the creation of two new exoskeletons for the treatment of physical...

Rousant Sherwood PH10T

William Law, Rousant Sherwood production manager, considers the cost of upgrading to this new PH10T motorised probe head from Renishaw to be “a small price to pay for the main player in our...

Making 3D printing plug and play

British engineering company Renishaw has obtained a compliance certificate from TÜV SÜD for its AM250 laser melting machine.

Manual probe head cable

This coiled cable has a 7-pin Amphenol plug at end 'A' and a 90° moulded plastic 5-pin DIN plug at end 'B'. It electrically connects Renishaw manual probe heads to the CMM quill.

Jingdiao's refusal to compromise on quality sees its business take-off

Beijing Jingdiao Company Ltd has collaborated with Renishaw as its business has continued to grow over the years, with the two companies working together to open up new pathways to innovation and...

UCC MMI (H-1000-5362) - legacy

The UCC MMI is an interface for use on manual CMMs to interface and connect encoder and probe signals to the PC. The complete range of Renishaw 2-wire kinematic touch-trigger probes are supported.

Jingdiao's refusal to compromise on quality sees its business take off

Beijing Jingdiao Company Ltd has collaborated with Renishaw as its business has continued to grow over the years, with the two companies working together to open up new pathways to innovation and...

Motorised probe head cable

These coiled cables have an in-line LEMO plug at end 'A' and a 90° Tuchel socket at end 'B'. They electrically connect Renishaw PH10T, PH10M or PH10MQ motorised probe heads to the CMM quill.

Better accuracy enables Godrej to redefine quality norms and help reduce costs

Accuracy and on time delivery of projects are key requirements for the tooling industry.

Rousant Sherwood production manager

William Law, Rousant Sherwood production manager, considers the cost of upgrading to this new PH10T motorised probe head from Renishaw to be “a small price to pay for the main player in our...

New Laboratory Measures Up for Heriot-Watt

A new manufacturing laboratory has opened at Heriot-Watt University aided by the donation of half a million pounds worth of equipment, software and training by Renishaw, a world leader in industrial...

Better accuracy enables Godrej to redefine quality norms and help reduce costs

Accuracy and on time delivery of projects are key requirements for the tooling industry.

Rousant Sherwood production manager

William Law, Rousant Sherwood production manager, considers the cost of upgrading to this new PH10T motorised probe head from Renishaw to be “a small price to pay for the main player in our...

FORTiS-N™ enclosed absolute encoder

Seeking an enclosed encoder system for small spaces? Discover Renishaw’s next generation FORTiS-N™ linear enclosed absolute encoder for space-limited applications.

FORTiS-S™ enclosed absolute encoder

Looking for an enclosed linear absolute encoder system for machine tools? Find out about Renishaw’s next generation FORTiS-S™ linear enclosed absolute encoder for use in harsh environments.

Renishaw launches super-productive RenAM 500 Ultra at Formnext 2023

Press release for release of new RenAM 500 Ultra model of metal AM machines

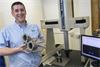

Custom Renishaw Raman probe interface deployed on the SNBL beamline

Part of the custom Raman probe deployed on the SNBL Beamline, ESRF, Grenoble, France.

Renishaw and Hartford combine to deliver intelligent, ‘smart factory’ solutions

Established in 1965, Hartford is Taiwan’s biggest exporter of CNC machining centres as well as being the country’s largest machining centre manufacturer.

Renishaw AM systems were used to realise the physical part

An image of a RenAM 500M with a worker.

Renishaw supports new US HTEC centre with performance testing tool

Haas, one of the world’s leading machine tool manufacturers, has boosted its Haas Technical Education Centre (HTEC) programme in the USA, with the opening of a dedicated HTEC teacher training centre...

Renishaw launches functional safety variant of FORTiS™ enclosed encoder

Press release announcing the launch of the FORTiS FS encoder.

inspection of a component using the Renishaw SP25 scanning probe

New approach to quality control reaps significant benefits for gear supplier to Bosch Rexroth and Case New Holland

Renishaw and Hartford combine to deliver intelligent, ‘smart factory’ solutions

Established in 1965, Hartford is Taiwan’s biggest exporter of CNC machining centres as well as being the country’s largest machining centre manufacturer.