Filter by

Results found for renishaw

PSU3 power supply unit

The PSU3 provides a +24V dc power supply for Renishaw signal transmission units, when a +24V dc power supply is not available from the CNC machine control.

REVO-2 (H-1000-7590)

REVO-2 is a dynamic measuring head and probe system from Renishaw. It is a revolutionary product designed to maximise measurement throughput whilst maintaining high system accuracy.

John Jeans CBE CEng non-executive director

The Board of Renishaw plc is pleased to announce the appointment of John Jeans CBE CEng as a non-executive director with effect from 11 April 2013.

ALSAM project aluminium lattice structures

Lattice test structures built on Renishaw AM250 metal AM system at The University of Nottingham, as part of the Aluminium Lightweight Structures via Additive Manufacturing (ALSAM) project

Games Workshop case study image

The two Renishaw Cyclone scanning machines are running un-manned 24 hours a day, seven days a week at the Wisbech, UK works of Games Workshop Tooling.

Motorcycle cylinder head machining - reduce scrap and increase machine productivity.

Case brief highlighting the typical challenges faced by an end-user in the automotive industry when machining motorcycle cylinder heads, and how Renishaw systems overcame these challenges.

UCC S5 universal CMM controller

UCC S5 universal CMM controller UCC comparison ■ Standard specification - Not available NOTE: Dimensions in mm (in).

UCC S3 universal CMM controller

Powerful 3-axis CMM controller featuring built-in touch-trigger interface, TP200 interface, SP600 and SP25M interface, PH10 PLUS head controller and temperature compensation.

Measurement accessories

A number of optical accessories are available to ease set-up, alignment and operation of your XL-80 laser measurement system.

Using HCU1

Using HCU1 Layout Key 1.

HR - Sigurnost

HR - Sigurnost Ključ ‡ Optički prozor UPOZORENJE: Ne dodirujte sonde (uključujući krakove za protutežu radi uravnoteživanja), držače pisaljke i druge module dok je REVO-2 glava uključena...

Gauging system accelerates COVID-19 test kit production

In the race to combat the global COVID-19 pandemic, the distribution of coronavirus test kits became a very high priority.

World’s first metal 3D printed bike in Guinness World Records

FTSE listed British engineering company Renishaw has been featured in the 2015 edition of Guinness World Records for manufacturing the world’s first 3D printed titanium alloy bicycle frame.

Sponsors of Trevithick Library, Cardiff University, with Carol Vorderman

Renishaw was represented at the official opening of the newly refurbished Trevithick Library at Cardiff University, by Chris Pockett (Group Marketing Services Manager) and Gareth Hankins (Manufactu...

Shrouk El-Attar

Shrouk El-Attar, an Electronic Design Engineer at Renishaw, has been shortlisted for the 2019 Institution of Engineering and Technology’s (IET) Young Woman Engineer of the Year Award.

Reflecting on the Additive Manufacturing industry

Stephen Crownshaw, Head of AM Sales at Renishaw, reflects on how the industry has developed in comparison with predictions and explores how AM will develop in the future.

Lord Green discusses 3D printing

Lord Green, Minister for Trade and Investment, described engineering company Renishaw as “an inspiring example to other businesses” on a recent visit to the company’s headquarters in Gloucestershire.

Next generation probing systems for machine tools - QE series

The QE series comprises an ultra-compact RMI-QE radio interface with a communication protocol future-proofed to support a new generation of Renishaw sensors and smart devices.

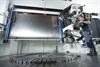

Mekall – Defence & telecommunications supplier ‘would not operate a machine without probes’

Mekall, a Scottish manufacturing services group uses HAAS machine tools, each one fitted with Renishaw touch probes, to service clients in the defence, aerospace, medical and telecommunications markets.

Team at Stonehenge

Some of the team that analysed the Altar Stone at Stonehenge overnight. From left to right; Prof Sergio Andò, Dr Jorge Diniz (Renishaw plc) and Dr Marta Barbarano.

Mekall – Defence & telecommunications supplier ‘would not operate a machine without probes’

Mekall, a Scottish manufacturing services group uses HAAS machine tools, each one fitted with Renishaw touch probes, to service clients in the defence, aerospace, medical and telecommunications markets.

RENGAGE™ and SupaTouch machine tool probing technologies: minimise cycle time, maximise productivity

Global engineering technologies company, Renishaw, will demonstrate its RMP400 machine tool probe in combination with its SupaTouch technology at MACH 2020 in the UK, from 20th - 24th April.

Shrouk El-Attar

Shrouk El-Attar, an Electronic Design Engineer at Renishaw, has been shortlisted for the 2019 Institution of Engineering and Technology’s (IET) Young Woman Engineer of the Year Award.

Martin Aerospace - New approach to manufacturing attracts royal interest

Martin Aerospace, a Rolls-Royce subcontractor, has employed high-accuracy Renishaw probes and a GSPS CNC Reporter™ process monitoring package to reduce machining lead times and improve consistency

Martin Aerospace - New approach to manufacturing attracts royal interest

Martin Aerospace, a Rolls-Royce subcontractor, has employed high-accuracy Renishaw probes and a GSPS CNC Reporter™ process monitoring package to reduce machining lead times and improve consistency

Tom Silvey, Apprentice of the Year, receiving award from Princess Anne (image courtesy Gloucestershire Media)

Tom Silvey, a 3rd Year apprentice at Renishaw, has won two awards at Gloucestershire’s inaugural Apprenticeships Awards, where the guest of honour was Her Royal Highness The Princess Royal.

The fundamentals of probing

Part of a series of brochures: This is a high level overview of Renishaw machine tool probes and the basics of how machine tool probes work and are used.

KMT Lidköping - Green energy giant grinds with micron precision

The massive KMT Lidköping VTG4000 grind-turn machine enables high precision wind turbine bearing production on a very large scale, with Renishaw encoders critical to accurate and rapid operation

Rotary axis

The massive KMT Lidköping VTG4000 grind-turn machine enables high precision wind turbine bearing production on a very large scale, with Renishaw encoders critical to accurate and rapid operation

Faster shop-floor inspection with AGILITY and REVO® 5-axis multi-sensor CMM system

This application note describes how the Renishaw AGILITY and REVO 5-axis multi-sensor system, is utilised for shop floor use and addresses the inspection challenges for automotive parts.

KMT Lidköping - Green energy giant grinds with micron precision

The massive KMT Lidköping VTG4000 grind-turn machine enables high precision wind turbine bearing production on a very large scale, with Renishaw encoders critical to accurate and rapid operation.

MSP RIC seminar event

Precision engineering and manufacturing technologies company, Renishaw, is pleased to announce that it will be hosting a technical seminar on Wednesday 5th June, focused on ‘machining the perfect part’.

ACR1 / ACR3 / FCR25 port replacement

Renishaw racks allow fast repeatable exchanging of probes and styli without the need for manual intervention. This leaflet covers the replacement of ports for ACR1, ACR3 and FCR25 racks.

UCClite-2 and UCClite (H-1000-5109) - legacy

The UCClite-2 is an addition to the Renishaw CMM controller product range. Utilising the UCC1 platform introduced in 1997, the UCClite-2 offers similar system performance and capability.

Faster quality inspection of a new gearbox design

This application note describes how the Renishaw AGILITY® S 12129 CMM, designed specifically for shop floor use, addresses the inspection challenges of a new design for gearbox manufacturing.

Trophy for Art Couture Painswick

Renishaw used its AM process to create the main trophy which was presented to the winner by Chris Pockett, Head of Communications. Image courtesy of Stroud News and Journal

Innovation Matters 2023

Renishaw uses its decades of experience in smart manufacturing and process control to help businesses in a range of industries to develop smarter processes for improved capability and productivity.

Case story - Green energy giant grinds with micron precision - banner image

The massive KMT Lidköping VTG4000 grind-turn machine enables high precision wind turbine bearing production on a very large scale, with Renishaw encoders critical to accurate and rapid operation

Tom Silvey, Apprentice of the Year, with other winners (image courtesy Gloucestershire Media)

Tom Silvey, a 3rd Year apprentice at Renishaw, has won two awards at Gloucestershire's inaugural Apprenticeships Awards, where the guest of honour was Her Royal Highness The Princess Royal.

PLC Award 2011 presentation - Best Technology winner

Picture shows, left to right; Ian Powell, Chairman and senior Partner, PwC; Delphine Currie, Partner, SJ Berwin; Tim Prestidge, Renishaw plc (winner); and Kate Silverton, presenter of the awards.

ADT Foundation Conference 2016

On 23rd and 24th September 2016 Renishaw plc will be working with the ADT foundation’s UK Regional Leadership Group as platinum sponsors and co-hosts of its 2016 conference.

Tom Silvey, Apprentice of the Year, with his award (image courtesy Gloucestershire Media)

Tom Silvey, a 3rd Year apprentice at Renishaw, has won two awards at Gloucestershire’s inaugural Apprenticeships Awards, where the guest of honour was Her Royal Highness The Princess Royal

The RECLAIM consortium

The RECLAIM project is being undertaken by a consortium of eight organisations - Renishaw, Delcam, Electrox, TWI, Precision Engineering Technologies, Cummins Turbo Technologies, Airfoils Technology...

Laser diagonal testing

This presentation explains how Renishaw laser calibration systems can be used to check machine positioning performance along machine diagonals, in accordance with the B5.54 and ISO 230-6 standards.

Janez Novak, left, and Sir David McMurtry cutting the ribbon at the new RLS facilities

Janez Novak, Director of RLS, and Sir David McMurtry, Chairman and Chief Executive of Renishaw cutting the ribbon at the opening of the new RLS facilities in Komenda, Slovenia

FORTiS-N™ enclosed absolute encoder

Seeking an enclosed encoder system for small spaces? Discover Renishaw’s next generation FORTiS-N™ linear enclosed absolute encoder for space-limited applications.

FORTiS-S™ enclosed absolute encoder

Looking for an enclosed linear absolute encoder system for machine tools? Find out about Renishaw’s next generation FORTiS-S™ linear enclosed absolute encoder for use in harsh environments.

PICS (9W 'D' socket)

PICS (9W 'D' socket) Pin number Function 1 /PICS STOP/ (active low) 2 /PICS PPOFF/ (active low) probe power off 3 0 V 4 PICS LED anode 5 Probe signal 6 Reserved 7 /PICS PDAMP/ (active low)...

AC3 integration

AC3 integration NOTE: SP600 / AC1 or AC2 identification resistance is 30 kΩ.

UCC MMI general wiring standards

UCC MMI general wiring standards Preparations Before beginning the installation of the UCC MMI check the following items: Ensure that all connecting cables, test equipment and software are available...